|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

4-187. PRESSURE SENSOR GAUGE

THIS TASK COVERS:

a. Removal

c. Installation

b. Cleaning and Inspection

TOOLS REOUIRED

EQUIPMENT CONDITION

Too[ Kit, General Mechanics, Automotive

Main Engine Shutdown (see para 2-12.)

(Appendix B, Section III, Item 1)

APU Shutdown (see para 2-16.)

Batteries Disconnected (see para 4-114.)

MATERIALSIPARTS REQUIRED

Dry Cleaning Solvent (Item 3, Appendix E)

Pipe Sealant (Item 2, Appendix E)

a. Removal.

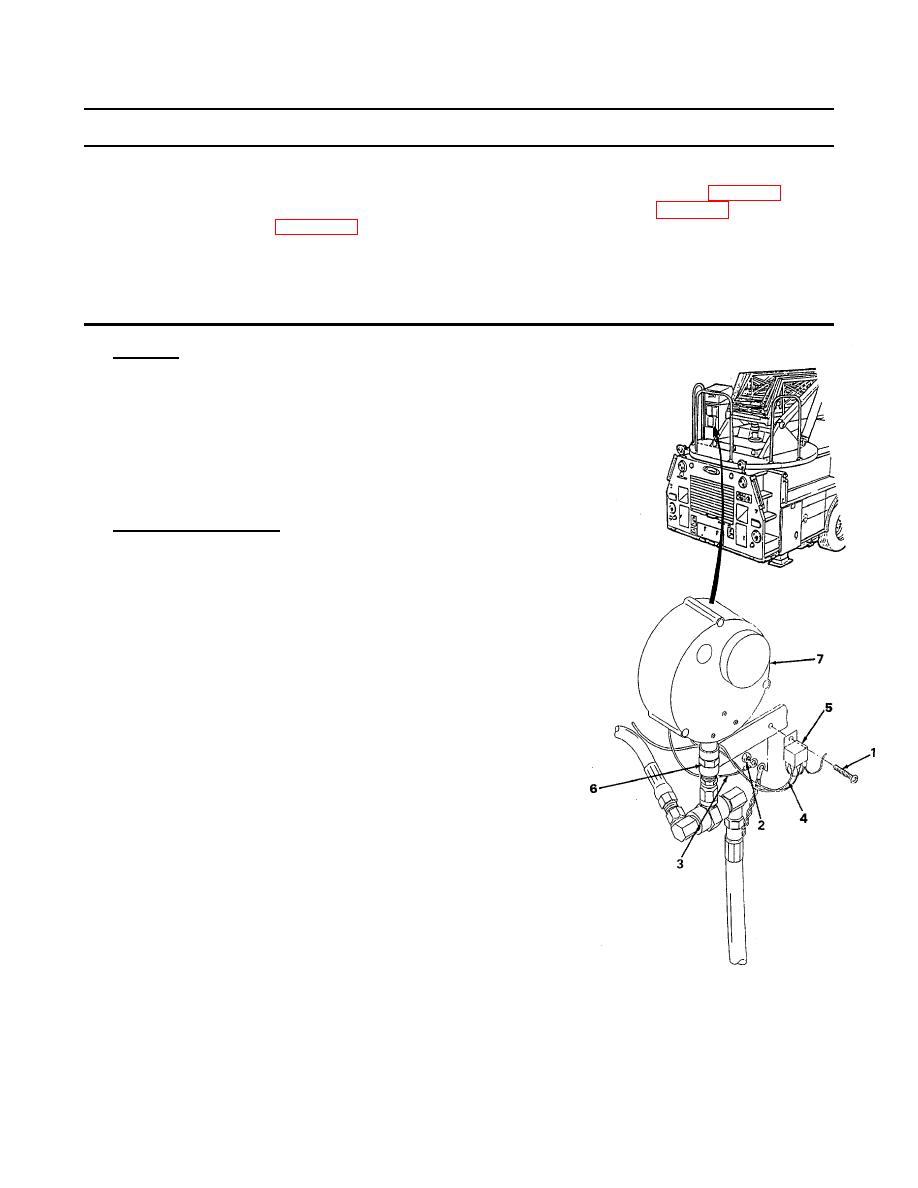

(1) Remove screw (1) and nut (2) disconnecting white

ground wire (3) from central stand bracket.

(2) Disconnect gauge black wire (4) from Bosch relay (5).

(3) Use open end wrench to unscrew 1/2" coupler (6) and

remove coupler (6) and gauge (7) as an assembly from

control stand bracket.

b. Cleaning and Inspection.

WARNING

Dry cleaning solvent P-D-680 is potentially dangerous.

Avoid repeated and prolonged breathing of vapors and skin

contact with the liquid. Do not use near open flame, arcing

equipment or other ignition sources. Always wear eye

protection and protective clothing. The flash point of P-D-

680 is 100 to 138 deg F (30 to 50 deg. C).

(1) Clean gauge with a shop cloth dampened in dry

cleaning solvent (Item 3, Appendix E)

WARNING

Death or serious injury could occur if compressed air is

directed against the skin. Do not use compressed air for

cleaning or drying unless the pressure is/has been reduced

to 30 psi (2.11 kg/cm2) or less. When working with

compressed air, always use chip guards, eye protection and

other personal protective equipment.

(2) Dry gauge with compressed air.

4-480

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |