|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

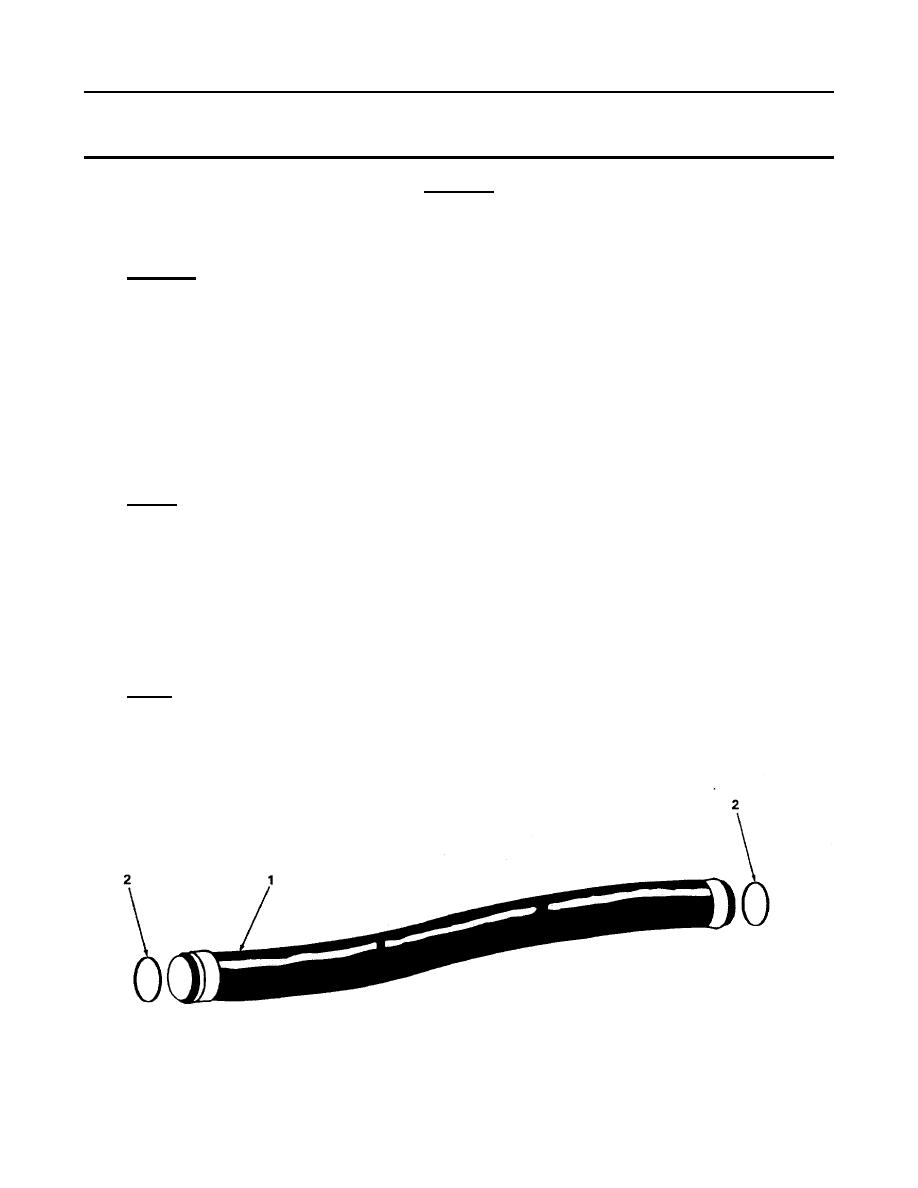

4-10. HARD SUCTION HOSES

This task covers:

a. Inspection

c. Repair

b. Testing

CAUTION

If there is even suspicion of damage to sleeve or couplings,

replace hose.

a. Inspection.

NOTE

Hard suction hoses are located in equipment storage rack at

rear of truck.

(1) Visually inspect hose (1) for deep cuts or holes.

(2) To inspect swivel gaskets (2) remove gaskets and pinch together between the thumb and index

fingers; check for cracks, creases, and general elastic deterioration.

(3) Install gaskets (2) in hose.

b. Testing.

(1) Cap hose end and connect to a vacuum source.

(2) Gradually increase vacuum to 23 inches of mercury for three minutes.

(3) Check hose for leaks and/or distortion of sleeve.

(4) To pressure test hose, cap hose end and connect to a water pressure source.

(5) Gradually increase pressure to 200 psi (1371 kPa) and hold for 5 minutes.

(6) Check hose for leaks and/or distortion of sleeve.

c. Repair.

(1) Install new gaskets (2) if found defective or damaged.

(2) Replace hose if found defective during inspection or testing.

4-160

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |