|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

STEERING GEAR

back adjusting screw out one turn and measure

torque required to rotate worm shaft (17), thru 90

deg. each side of center of steering gear travel. This

torque must not exceed 1.7 Nm (15 in.lbs.). Tighten

adjusting screw and torque nut (38) to 95-109 N

m

(70-80 ft.lbs.), after tightening nut torque to rotate

worm shaft must rise .45-.79 Nm (4-7 in.lbs.) above

torque checked previously (Fig. 35).

30.

Apply a generous amount of clean wheel bearing

grease to bearing race inside side cover (58) to retain

bearing rolls; assemble forty-four bearing rolls.

Grease must retain rolls.

31.

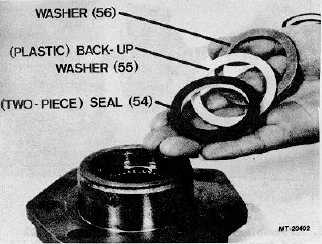

Assemble washer (56), back-up washer (55), two-

piece seal (54) and retaining ring (53) into side cover

(58). Assemble two-piece seal (54) with "oil side"

towards retaining ring (Figs. 36 and 37).

Fig. 37

38.

Apply clean grease to short bearing area of sector

shaft (50) and insert into side cover (58); screw

adjusting screw (51) into side cover until it reaches

solid height. The side cover should rotate freely on

sector shaft with no appreciable axial movement

(Fig. 38).

Fig. 38

33.

Assemble nut (59) onto adjusting screw (51) a few

threads. (Final adjustment must be made later.)

34.

Assemble vent plug (60) in hole provided in side

cover (58), press vent plug in flush with side cover.

35.

Apply clean grease to side cover gasket (57) and

assemble onto side cover (58). Grease must hold

side cover gasket in place.

36.

Rotate worm shaft (17) to position rack piston (31) in

center of steering gear travel. Align center tooth on

sector shaft (50) with third notch from seal ring (29)

end on rack piston and assemble sector shaft with

side cover attached into housing (20); care must be

taken to not pinch side cover gasket and to be certain

that sector shaft goes thru housing bearing (21)

without knocking out bearing rolls (Figs. 39 and 40).

CTS-2717 Page 12

PRINTED IN UNITED STATES OF AMERICA

|