|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

PROPELLER SHAFT

LUBE SPECS

DON'T NEGLECT DRIVE SHAFT LUBRICATION

Lack of adequate or proper lubrication is among the

most common causes of U-Joint and drive shaft failure!

Proper servicing of the drive shaft is an essential part of

vehicle maintenance and should not be overlooked in routine

shop procedure.

UNIVERSAL JOINTS

IN THE VEHICLE OR APPLICATION

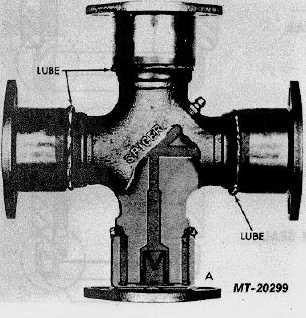

To insure proper lubrication of all four bearing

assemblies on universal joints, it is essential that mechanics

add lubricant until it appears at all journal cross bearing seals

(Fig. 10). This assures removal of dirt particles and other

contaminants that may find their way into the bearings and

indicates to the mechanic that the bearings are fully

lubricated. Do not assume that bearing cavities have been

filled with new lubricant unless flow is noticed around all four

bearing seals! Journal cross seals are designed to relieve.

However, if all the seals do not "pop" when being lubed, move

the driveshaft laterally in all four directions and pull or push on

the drive shaft in the direction opposite to the journal cross

seal not relieving while lube gun pressure is being applied to

the alemite fitting. An increase in line pressure may also be

necessary.

Fig. 10

DRIVE SHAFT ASSEMBLY

Factory assembled drive shafts are lubricated at the

plant prior to shipment. However, shipping, handling and

installation of the drive shaft assembly into the vehicle usually

results in some loss of lube. Therefore, it is recommended

that all universal joints be relubricated after installation of the

drive shaft prior to putting vehicle in service.

JOURNAL AND BEARING KITS

Replacement universal joint kits contain only enough

grease to provide needle bearing protection during storage. It

is

therefore

necessary

to

completely

lubricate

each

replacement kit prior to assembly, into the drive shaft yokes.

Each journal cross lube reservoir should be fully packed with

a recommended grease and each bearing assembly should

also be wiped with the same grease; filling all the cavities

between the rollers and applying a liberal grease coating on

the bottom of each race. After the kits are installed into the

driveshaft yokes and prior to placing into service, they should

be relubed, through the zerks, using the same grease.

LUBRICANT

For center bearings, slip joints and universal joints

use IH 251 HEP grease or equivalent NLGI #2 multi-purpose

grease.

RELUBE CYCLES

Relubrication cycles for driveshaft universal joints

and slip splines will vary with service requirements and

operating conditions. Refer to Operator's Manual.

SLIP JOINT LUBRICATION

Relube spline at intervals prescribed in Operator's

Manual. Apply grease gun pressure to lubrication zerk until

lubricant appears at pressure relief hole in welch plug at

sleeve yoke end of spline (Fig. 11). At this point, cover

pressure relief hole with finger and continue to apply pressure

until grease appears at sleeve yoke seal (Fig. 12). This will

insure complete lubrication of spline.

CTS-2730 Page 10

PRINTED IN UNITED STATES OF AMERICA

|