|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

INSTRUMENTS

FLEX-PRINTED CIRCUIT

One component of instrument cluster which is integral

with cluster body itself is the flexprinted circuit. This tough

flexible plastic film is cemented to cluster body to simplify

instrument wiring (25 electrical connections are replaced by

one). However, if the need should arise for electrical trouble

shooting, individual circuits on the printed circuit are easily

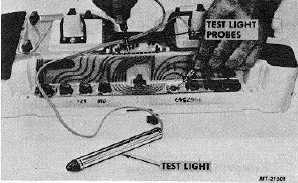

checked. This is accomplished with cluster removed (Fig. 12).

Fig. 12 Checking Printed Circuit Continuity

Testing

Obtain SE-2060-4 Test Light or equivalent tester and

position test probes on a selected circuit in a manner similar to

that shown in Fig. 12. If test light illuminates, circuit is

unbroken, or if test light fails to illuminate circuit is broken.

Check each circuit in turn and if a broken circuit is found,

instrument cluster body must be replaced.

Replacement

Since printed circuit is cemented to and integral with

instrument cluster body, the printed circuit and cluster body are

available for replacement as a complete assembly only. Where

replacement is required, obtain new instrument cluster body

assembly and transfer all gauges and light bulbs from old

cluster body to new. Individual parts of the instrument cluster,

available for service, are shown in Fig. 13.

SPEEDOMETER

The speedometer used on this vehicle indicates miles

and kilometers per hour. Distance traveled is recorded (in

miles*) on an odometer. Speedometer is driven by a semi-rigid

cable connected to a set of gears in vehicle transmission.

Specified gears match the particular truck model anti take into

consideration such other factors as

tire size and rear axle ratio, The semi-rigid cable which

connects transmission driven gear to the speedometer head

consists of an outer case and an inner core. Odometer records

up to 999,999 miles* and returns to zero. School bus models

record 99,999,9 miles.* (*Total metric speedometers record

kilometers.)

SPEEDOMETER ADAPTER

Should the need arise for changing a truck axle ratio or

tire size, a corresponding change must also be made to the

speedometer drive. This is accomplished by changing the

speedometer adapter and in some instances the driven gear in

the truck transmission. Information for finding the correct

adapter and driven gear can be found in the Speedometer

Section of the Parts Catalog.

TACHOMETER

An electrical or mechanical tachometer (not standard for

all vehicles) is also located in the instrument cluster to record

engine RPM (Revolutions Per Minute). This instrument enables

driver to keep engine speed within an efficient operating range.

The mechanical tachometer is driven by a flexible shaft

connected to an adapter or driving unit located on engine

(distributor shaft for gasoline engines or air compressor

injection pump, auxiliary shaft, etc. for diesel engines).

The electric tachometer reads the same as the

mechanical unit but receives electrical impulses by wire instead

of rotating cable. These impulses are received from a sender

unit mounted on the engine and using the mechanical

tachometer drive take off.

SPEEDOMETER AND TACHOMETER CABLES

A semi-rigid type cable is used for both speedometer and

tachometer on S-Series Trucks.

This cable consists of (1) an outer case or cable

assembly with nut and ferrule at lower end and a quick

disconnect ferrule at upper end, and 2) a wire wound flexible

inner cable or core assembly with squared drive at upper end

and floating tip (Fig. 14) at lower end. The floating tip which is

detachable from cable allows core to float and thereby minimize

thrust on speedometer or tachometer head. (Speedometer

cable assemblies are sometimes made in two sections for

assembly purposes.)

The cable outer case is formed from an inner nylon liner,

an intermediate ply of wire braid and an outer polypropylene or

polyethylene case (Fig. 15).

CTS-2735 Page 6

PRINTED IN UNITED STATES OF AMERICA

|