|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

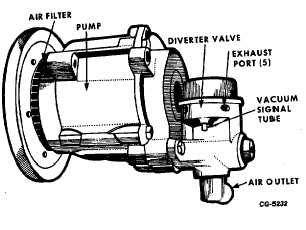

Fig. 71 Air Injection Pump With Diverter Valve

(Except California)

(1)

Disconnect left bank air injection hose from air

manifold check valve and connect air pump output

tester SE-2498 to end of hose.

(2)

Disconnect left bank pressure limiting hose from air

cleaner and plug end of hose.

(3)

Connect tachometer to engine.

(4)

Operate engine at speed specified (see Emission

Control Tune-Up Specifications)

(5)

Observe pressure indicated. If air pressure does not

exceed minimum specification (see Emission Control

Tune-Up Specifications) perform the following steps

a, b, c and d.

a.

Check air hoses for leaks. Check diverter

valve for, external leaks. If leaks are found,

replace hose(s) and/or diameter valve and

repeat steps 4 and 5.

b.

Disconnect air hose (connecting air pump

outlet to diverter valve inlet) from diverter

valve and connect air pump output tester SE-

2498 to end of hose.

c.

Operate engine at specified speed (see

Emission

Control

System

Tune-Up

Specifications)

and

observe

minimum

pressure.

(1)

If air pressure is less than specified minimum (see

Emission Control System Tune-Up Specifications),

air pump is faulty and must be replaced. When

installing a new air pump or adjusting the air pump

belt tension, do not pry on the pump housing.

(2)

If air pump pressure is higher than specified

minimum (see Emission Control System Tune-Up

Specifications), diverter valve is faulty and must be

replaced.

d.

Connect air pump output tester SE-2498 to air

injection hose removed from check valve.

Connect air injection hose from air pump to

diverter valve inlet and repeat steps 4 and 5.

(6)

With the engine operating at speed specified,

observe the pressure gauge. Multiply observed

pressure by .7 to obtain multiplied pressure.

(Example: Observed pressure is 6 PSI and multiply

by .7. 6 x .7 = 4.2 PSI multiplied pressure)

(7)

Remove plug in the pressure limiting hose and

observe the pressure gauge.

a.

If observed pressure in step 7 is higher than

multiplied pressure in step 6, diverter valve is

acceptable for further use.

b.

If observed pressure in step 7 is lower than

multiplied pressure in step 6, diverter valve is

faulty and must be replaced.

(8)

With the engine operating at speed specified (see

Emission Control System Tune-Up Specifications),

remove vacuum hose from diverter valve and check

for vacuum pull at the end of the hose. If no vacuum

is felt, check for restriction in vacuum hose, vacuum

manifold and carburetor vacuum port. Repair as

needed.

CGES-215 Page 41

PRINTED IN UNITED STATES OF AMERICA

|