|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

will be necessary to increase or decrease belt tension

as required.

(5)

Before changing belt tension, repeat Step (3) several

times to become familiar with gauge operation.

Observe gauge reading each time operation is

repeated. Check tension of both belts when so

equipped.

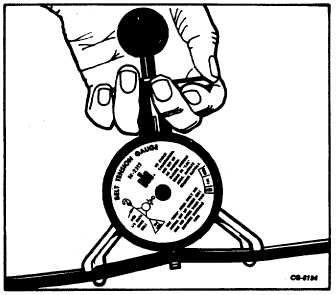

Fig. 64 Checking Belt Tension With SE-2312 Gauge

To establish tension of a loose belt apply SE-2312

gauge to belt and make the adjustment. Tighten belt until

proper area for belt is indicated at index mark on gauge. Lock

adjustment and recheck belt tension. Readjust as necessary.

When using SE-2312 belt tension gauge, remember to

set new belts (belt with less than two minutes running time) to

the NEW area on gauge face and used belts (more than two

minutes running time) to USED area on gauge.

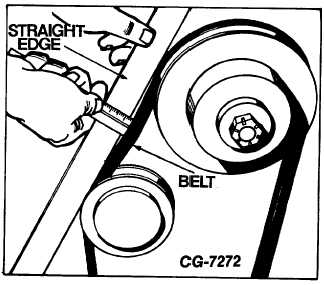

Belt tension may also be checked by using a straight

edge and scale as illustrated (Fig. 65).

Approximately 12.7 mm (½ inch) deflection should be

measured. The deflection measurement should be made

between pulleys at mid-point of longest belt span.

Fig. 65 Measuring Belt Tension

1. Straight Edge

2. Belt

INSPECT AIR PUMP AIR FILTER(S)

Inspect air pump centrifugal air filter; if clogged or

damaged, air pump centrifugal filter can be replaced as

follows:

(1)

Hold pump pulley from turning and remove pulley

mounting bolts.

(2)

Insert needle nose pliers and pull filter fan from hub

(Fig. 66). Care should be taken to prevent

fragments of the fan from entering the air intake hole.

(3)

Install new filter fan by drawing it on with the pulley

and pulley bolts (Fig. 67). Do not attempt to install

the filter by hammering or pressing it on.

(4)

Draw filter fan down evenly by alternately tightening

the pulley mounting bolts. Make certain that the

outer edge of the filter slips into the pump housing.

A slight amount of interference with housing bore is

normal.

(5)

Hold pulley from turning and torque pulley bolts to 34

N. m (25 ft. lbs.). The new filter may squeal up on

initial operation until its outside diameter sealing lip

has worn in.

CGES-215 Page 38

PRINTED IN UNITED STATES OF AMERICA

|