|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

15C.

EGR Maintenance Indicating System (V-345 and

V-392 Engines Only)

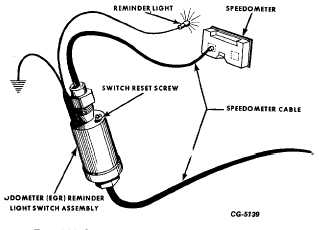

This system is used to alert the vehicle operator, after

each 19200 Km (12,000 miles), that the EGR system must be

serviced to insure that it is operating properly.

The system consists basically of a switch, or revolution

counting device, and an indicating light (Fig. 57).

Fig. 57 EGR Maintenance Indicating System

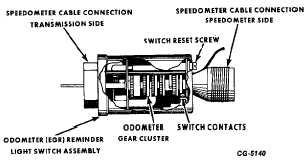

The switch is triggered by a counter mechanism,

similar to an odometer, which is connected in series with the

speedometer cable. After 19200 Km (12,000 miles), electrical

contacts inside the switch snap together and complete the

circuit to the indicator light (Fig. 58).

Fig. 58 Reminder Light Switch Assembly

The red indicator light, which has the words "Service

EGR" on the face, is mounted on the instrument panel. When

lighted, the letters are easily visible even in the daylight.

After the EGR system maintenance is performed, the

indicator light can be turned off and the switch reset by turning

the reset screw (Fig. 58) about 450 (¼ turn). This zeros the

switch's odometer gears and opens the electrical contacts.

The switch is then ready to count the next 19200 Km (12,000

mile) interval.

A circuit that tests the indicator light bulb during engine

starting is utilized, the same as the brake warning light.

16. Check Curb Idle Speed and Air; Fuel Mixture and

Adjust, as necessary.

Adjustment procedure with Exhaust Analyzer

Idle speed and fuel mixture adjustments must be made

with parking brake applied, air cleaner in place, transmission

in neutral and air conditioning "OFF".

When making idle adjustments on California engines,

disconnect vacuum hose from vapor storage canister and

plug end of hose. After idle adjustments have been made,

remove plug and reconnect hose to canister.

To compensate for fuel and temperature variations when

setting idle mixture, observe these precautions:

a.

Do not idle engine continuously for more than three

minutes at one time.

b.

After each three minutes of idling, increase engine

speed to 2000 rpm for one minute.

c.

Continue with idle adjustment procedure. Do not idle

engine for more than three minutes without repeating

Step b.

Winter grade gasolines, being more volatile than summer

grade, can yield vapors which result in excessively rich or

erratic

air/fuel

mixtures,

particularly

at

high

engine

temperatures. Because of this, care must be taken when

making carburetor idle mixture adjustments with the exhaust

analyzer. Attempts to adjust the idle mixture screw(s) leaner

to overcome a rich mixture caused by evaporation of winter

grade fuel at high engine temperatures can result in an

extremely lean mixture and associated starting and driveability

problems when vehicle is cold. Therefore, with winter grade

gasolines,

CGES-215 Page 32

PRINTED IN UNITED STATES OF AMERICA

|