|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

e.

Measure battery terminal D.C. voltage with engine at

idle speed and record.

f.

If coil positive terminal voltage is less than battery

terminal voltage by more than .5 volts, replace or

repair primary wiring, ignition switch or firewall

connector as required. Recheck coil output voltage.

If not satisfactory, proceed as follows:

g.

Measure ignition coil primary resistance. The

resistance from positive terminal to negative terminal

with ignition switch off should measure between 1.2

and 1.4 ohms. If resistance is outside these limits,

replace coil.

h.

Measure secondary resistance of ignition coil by

measuring between the positive terminal and the

secondary tower connector. The resistance should

measure between 9.4 and 11.1 thousand ohms. If

the resistance is outside these limits, replace coil.

i.

Off-Engine Coil Check: The ignition coil can be

removed from the engine and checked with SE2576 or

equivalent test equipment.

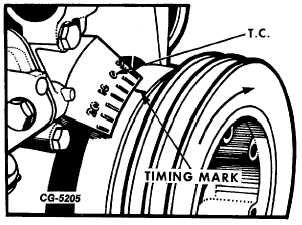

11. Check Initial Advance and Adjust if necessary.

a.

Connect timing light.

b.

Disconnect and plug vacuum advance hose.

c.

Start engine and operate until normal operating

temperatures are reached.

d.

Observe engine idle speed. Speed must be within

specifications (see Tune-Up Specifications); adjust

speed to specifications, if necessary.

e.

Observe initial advance with timing light.

f.

Loosen distributor clamp and adjust to specifications,

if necessary (see Emission Control System Tune-Up

Specifications). Tighten distributor clamp and

recheck initial advance.

Fig. 40 Typical Location of Timing Marks

g.

MV-446 engine, reconnect vacuum advance hose

and adjust speed to Tune-Up Specification, if

necessary.

Other

engines,

adjust

speed

to

specifications

with

vacuum

advance

hose

disconnected (Step b).

h.

Stop engine. Reconnect vacuum advance hose (if

necessary) and remove timing light.

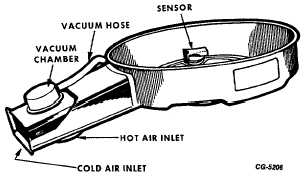

12. Check Operation of Inlet Air System Valve and

Service or Replace, if necessary.

Procedure for servicing the sensor controlled vacuum

chamber type air cleaner is as follows:

(Canada Scout Vehicles)

a.

Test should be conducted when ambient temperature

of the vehicle is less than 24 deg. C (75 deg. F) and

engine started cold. Air cleaner must have all hoses,

piping and cover in place. No leaks permitted.

Fig. 41 Sensor Controlled Vacuum Chamber Type Air

Cleaner

CGES-215 Page 24

PRINTED IN UNIT ED STATES OF AMERICA

|