|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

GENERAL

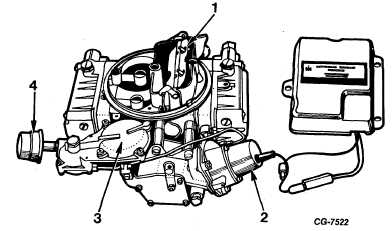

Figure 5 Model 4150EG Carburetor with Electronic Vacuum Modulating Type Governor

1. Choke Valve

3. Secondary Control Valve Assembly

2. Governor Solenoid Assembly

4. Control Valve Air Cleaner

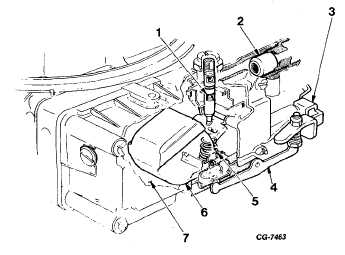

Figure 6 Typical Fuel Inlet System

1.

Needle and Seat

5.

Float Spring

Assembly

6.

Float and Lever

2. Filter Screen Assembly

3. Accelerating Pump

7.

Fuel Bowl

Operating Lever

4. Accelerating Pump

Cover Lever

Idle System

Primary Side. The 4150 series carburetors utilize two identical

idle systems, one for each primary bore. At idle, normal air

pressure in the primary float chamber causes

the fuel to flow through the idle system to the greatly reduced

pressure area below the throttle plate. Fuel flows from the float

chamber through the main jet into the small horizontal passage

that leads to a vertical passage.

Fuel flows up the idle well passage past the idle feed

restriction. The fuel then is mixed with incoming air from the

idle air bleed. This fuel and air mixture flows down a vertical

passage to the idle transfer passage and is discharged into the

throttle bore below the throttle plate. (Fig. 7)

Secondary Side. Because of driving habits, some drivers would

use the secondary side very little. If the secondary system

remains inoperative over long periods the system may become

blocked with gum and carbon formations. To prevent this

condition, an idle system is incorporated on the secondary side.

Fuel flows from the secondary fuel bowl through the

main jet, up the idle well and through the idle feed restriction.

Then it crosses a horizontal passage and blends with idle air

from the idle air bleed. This fuel-air mixture flows down a

vertical passage to the idle adjusting needle.

Part of this mixture flows into the idle discharge passage

and part into the idle transfer passage. The fuel-air is

CGES-125-T Page 6

PRINTED IN UNITED STATES OF AMERICA

|