|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

FUEL SYSTEM

After servicing filter element, reset signal (red band) by

pressing reset button and then releasing. This allows red signal

band to again rise above window.

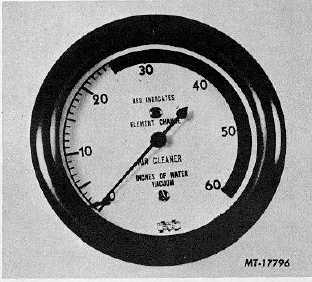

Where a direct reading air cleaner restriction gauge (Fig.

10) is used, the maximum allowable restriction is 25 inches of

water measured at the air cleaner outlet during any phase of

engine operation. When this happens, filter element service is

required.

Fig. 10 Air Cleaner Restriction Gauge

SERVICING

NOTE: Refer to the applicable owner's manual to obtain

recommended mileage intervals for air cleaner element

replacement and service.

Modulated Dry Type Air Cleaner

Service of modulated dry type air cleaner paper element

is limited, consisting mainly of checking the element for

punctures or splits by looking through element toward light.

Tap element-lightly on a flat surface or use low air pressure to

remove dirt particles. Do not wash or oil element.

Operation of the vacuum chamber and temperature

sensor may be checked by conducting the following tests.

NOTE: Tests should be conducted with engine started

from cold and ambient temperature of vehicle being not

less than 40 F. Air cleaner must have all hoses, piping

and cover in place. No leaks permitted.

1.

With engine off inlet tube damper should be in full

down position to close heat tube inlet pipe from

exhaust manifold stove. Damper position can be

determined by looking in end of inlet tube and should

be parallel to tube bottom. If damper assembly is not

in the correct position, vacuum chamber should be

removed and damper movement loosened. Replace

vacuum chamber and recheck damper position.

2.

Start engine and note that damper has rotated up to

close off cold air inlet. Observe damper position by

looking in the inlet tube. If damper did not immediately

close cold air inlet, shut off engine and disconnect the

two hoses from sensor. Connect the two hose ends

together using suitable tubing.

Restart engine and again check damper location. If

damper fully closes cold air inlet, temperature sensor

is defective and must be replaced. If damper did not

close cold air inlet, sensor is okay but damper has bind

or vacuum chamber is defective. Remove vacuum

chamber and check damper for free movement. If

damper moves freely, replace vacuum chamber.

3.

After a cold start operate engine for 10 minutes at

medium RPM. When engine is at normal operating

temperature, slow engine to idle and observe position

of inlet tube damper. If damper has not rotated all or

part way down to allow some cold air to enter inlet

tube, replace temperature sensor.

Vacuum Chamber Replacement (Fig. 11)

Vacuum chamber is replaced by bending tab nearest

inlet tube entrance down from inside of tube. Disconnect

vacuum hose and lift vacuum chamber, sliding rear tab out of

its slot and disengaging damper hook from damper.

The new chamber is attached by engaging hook in

damper, sliding rear tab into its slot and fitting front tab into

place. A spring preload should be felt when vacuum chamber is

pressed firmly against top of inlet tube. If no preload is felt,

check the installation or

CTS-2056N Page 5

PRINTED IN UNITED STATES OF AMERICA

|