|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

FRAMES

Riveting

Hot rivets are acceptable, as they can be more easily

driven with hand tools. Cold rivets should only be used where

tools of sufficient power to properly set the rivets are provided.

Rivets should be from 50% to 100% as heavy in diameter

as the total thickness of the plates to be riveted.

Welding

Electric arc-welding is recommended for all frame

welding. The reinforcements should be welded to the frame

after the reinforcements are riveted. All unused holes should

be filled with welding material. The welding rod should be

substantially the same material as that used in the frame.

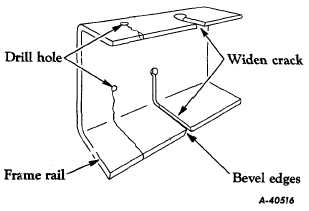

Preparation Of Frame For Repair

Before welding the reinforcement to the cracked section

of the frame side rail, certain preparations are necessary to

insure strength and stableness of repair. To prevent further

spreading of the crack, a hole should be drilled at the starting

point of the crack, Fig. 4. Widen the crack its full length,

using two hacksaw blades together. Groove or bevel both

sides of the crack to permit the weld to penetrate to the

surface

and

establish

a

solid

contact

between

the

reinforcement and the frame side rail. Grooving can be

accomplished by grinding or with a cape chisel.

Fig. 4-Showing Method of Drilling Frame Rail to Stop

Progress of Crack. Also shows Method of

Preparing Crack for Welding.

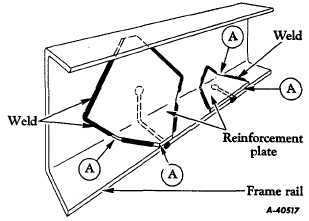

Fig. 5-Suggested Types of Reinforcing Plates and

Method of Attaching to Frame Rail.

IMPORTANT: Do not weld into the corners of the frame

or along the edges of the frame side rail flanges "A", Fig. 5.

Welding at these points tends to weaken the frame and

encourage development of new cracks.

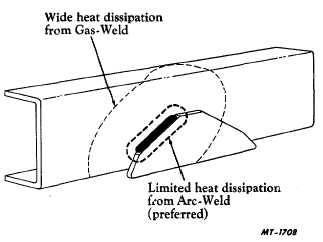

Use only the shielded-arc method for all frame welding.

Heat generated during welding is localized and burning of

material is minimized whenever this method is used. (Fig. 6)

Additional advantages are that the finished weld can be

ground, filed, and drilled as necessary.

With the reinforcement positioned in the frame side rail,

follow the welding patterns shown in Fig. 5 as closely as

possible.

Fig. 6-Weld Sample Showing Lower Heat Dissipation Possible

with Shielded Arc Welding.

CTS-2037-HA Page 4

PRINTED IN UNIT ED STATES OF AMERICA

|