|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

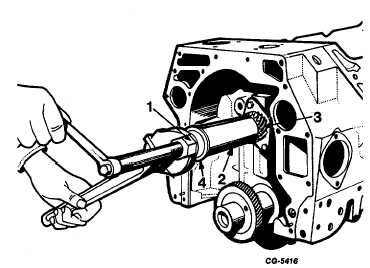

Fig. 123 Installing Distributor Drive Gear Using SE-1900 Tool

Set with Thrust Bearing

1.

Nut

3.

Distributor drive gear

2.

Sleeve

4.

Thrust bearing

2.

Install fuel pump cam against distributor drive gear

on camshaft using SE-1900-14 sleeve with SE1900-

16 adapter and thrust bearing in a manner similar to

Step 1.

3.

Install camshaft gear against fuel cam on camshaft

using SE-1900-14 sleeve with SE-1900-16 adapter

and thrust bearing in a manner similar to step 1.

4.

Install camshaft gear alien screw and torque to

specified torque. See "Torque Chart."

Crankshaft Bearings

The bearing inserts used in this engine are selective

fit and require no line reaming upon installation. The bearings

are available for service in standard and undersizes for use on

journals that have been reground.

If inspection revals badly worn or scored bearings,

replace the bearings. The installation of new bearings must be

closely checked to maintain the proper clearance between the

journal and the bearing surface. A convenient and accurate

method for checking the clearance is with the use of

Plastigage.

A. General Fitting Procedures

When wear reduces the bearing-tocrankshaft running

clearance, undersize precision-type bearing shells should be

installed. Premature bearing failure will result from attempts

to reduce journal-to-bearing running clearances by reworking

bearing caps, bearings or both. Such reworking will alter the

engineered fit of the bearing shells in their bores and destroy

the specifically desired "crush."

When installing precision-type connecting rod or

main bearings, it is important the bearing shells fit tightly in

the bore. The bearing manufacturer makes the diameter at

right angles to the parting line slightly larger than the actual

diameter of the bore into which they are assembled to

accomplish this. When the assembly is drawn up tight, the

bearing is compressed assuring a positive contact between

the bearing back and the bore. This increased diameter is

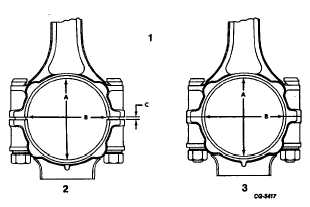

referred to as bearing "crush," Figure 124.

Fig. 124 Illustrating Bearing Crush

1.

Difference between

2.

Diameter (A) at

diameters (A) and

right angles to

(B) is bearing

parting lines

crush (C)

greater than dia-

meter (B).

3.

With bearing cap

drawn up tight

diameters (A) and

(B) equal.

CGES-210 Page 49

PRINTED IN UNITED STATES OF AMERICA

|