|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

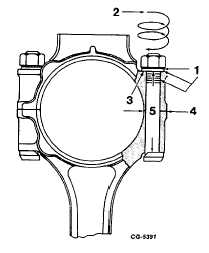

to a specified torque is to obtain tension in the bolt, Figure 98,

which in turn developes a clamping load or preload that

exceeds any possible loading imposed on parts due to engine

RPM. In other words, the connecting rods must "hang on" to

the crankshaft and suffer all the strains of intertia and cylinder

combustion impulse without permitting the least movement or

flexing of the rod cap, bolts or nuts. At the same time, torque

applied must be within the capacity of the parts (bolt, nut,

caps and connecting rods) to withstand these loads.

Fig. 98 Connecting Rod Cap and Bolt Details

1.

Friction

4.

Clamped

2.

Torque

5.

Tension

3.

Washer

In tightening connecting rod bolts and nuts to their

specified torque figure, a definite loading is obtained between

the connecting rod and cap. Specially designed bolts, nuts

and washers manufactured from selected materials permit the

application of this loading without undue stretching of bolts.

There is a relationship between the torque specifications and

clamping effect or load to be applied providing certain

conditions exist.

These conditions center largely around the belt itself

and its care, pointed out as follows:

1.

Bolt and Nut Thread Condition:

Threads that are dry, excessively rough, battered or

that are filled with dirt require considerable effort just to rotate

the nut. Then when the clamping load is developed or the bolt

tension is applied, the torque reading mounts rap o-idly

(due to thread friction) to the specified figure without

approaching the desired bolt tension and maximum clamping

effect. Under these conditions the desired torque reading is

obtained, but the clamping effect might be far below

requirements, leading to bearing failure or to connecting rod

bolt breakage. The proper bolt tension and clamping effect

can never be attained if the nut is dry. The nut and bolt must

have a film of lubricant in the thread section to be considered

lubricated. It is recommended that new connecting rod bolts,

nuts and washers be used during reassembly. Due to the

close fit of the connecting rod nuts on the bolts, the slightest

thread imperfection increases the friction to the extent that

incorrect bolt tension is likely.

Connecting rod bolts and nuts must be cleaned of all

foreign matter including the anti-rust materials that may be in

the threads. Apply light engine oil to the threads to lubricate

before installation.

2.

Tightening of Connecting Rod Bolts, Nuts and

Washers

Tighten the connecting rod bolts, nuts and washers

alternately with the torque wrench to the specified torque.

Then release the torque load to zero and retorque to specified

torque. See "Torque Chart." If nut is overtightened enough to

stretch the bolt, the nut and bolt both must be replaced. Use

new rod bolts, nuts and flat washers in major engine overhaul.

The application of specified torque to any particular

bolt or nut which serves to hold or clamp two parts together

should be accomplished with a torque wrench known to be

accurate.

Piston Rings

The pistons used in the V-type engines have three

piston rings located above the piston pin. The compression

rings are located in the top grooves while the lower groove

accommodates the oil control ring. Select the proper rings for

the size of pistons to be used.

Prior to installing the rings on the pistons, each ring

must be checked for proper ring gap. Push the ring down into

the cylinder bore making sure the ring

CGES-210 Page 36

PRINTED IN UNITED STATES OF AMERICA

|