|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

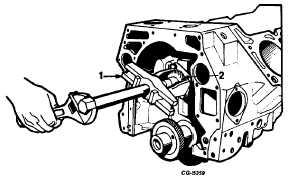

Fig. 66

1. Puller

2. Distributor Gear

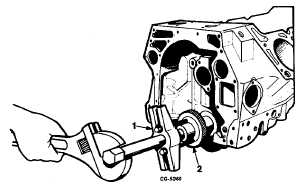

69.

Use SE-1368 Puller to remove the crankshaft gear,

Figure 67. If necessary, use an adapter or heavy flat

washer between the crankshaft and puller screw to

prevent damage to the internal threads.

Fig. 67 Using SE-1368 Puller to Remove Crankshaft Gear

1. Puller

2. Crankshaft gear

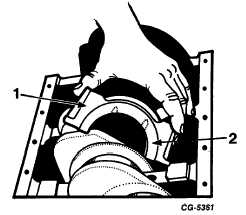

70.

The crankshaft bearing caps are numbered and

arrowed to the front to identify their respective positions

for reinstallation. The number three bearing cap

accommodates a thrust flange to limit crankshaft end

play, Figure 68. Remove bolts from bearing caps and

remove all main bearing caps.

71.

Lift the crankshaft straight up and out of the cylinder

block. Remove upper bearing inserts.

Fig. 68 Main Bearing Cap Removal

1. Number

3 main bearing cap

2. Thrust flange

ENGINE OVERHAUL

Cylinder Block

One of the most important phases of engine

reconditioning is the thorough cleaning and inspection of the

cylinder block.

Each machined surface of the cylinder block should be

cleaned of all old gasket material. The pipe plugs which seal

the oil passages should be removed and all passages

thoroughly cleaned.

Remove the main oil gallery plug and use SE-2334-2

Brush (3/8" diameter) to clean the main oil gallery, Figure 69.

Replace oil plug after coating with a suitable nonhardening

sealing compound.

Fig. 69 Cleaning Main Oil Gallery with SE-2334-2 Brush

1. Tappet oil galleries

3. Brush

2. Main oil gallery

CGES-210 Page 25

PRINTED IN UNITED STATES OF AMERICA

|