|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

INSTALLATION

When installing spark plugs, always be sure gasket seats and

threads are clean.

Using a torque wrench, tighten plugs to 2830 ft. lbs.

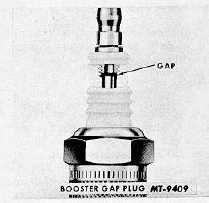

BOOSTER GAP PLUG

For the past several years auxiliary gap (Booster Gap)

spark plugs have been used in certain IH engines,

Fig. 19

Prior to IH approval, the Booster Gap design was

thoroughly tested and evaluated, at which time their anti-

fouling characteristics were firmly established.

What is a Booster Gap plug?

This plug has an internal air gap between the center electrode

and the terminal stud.

How do they work?

Most servicemen know that misfire will occur when a

conventional spark plug is fouled. As the coil attempts to build

up voltage on the "dirty" firing end, it "sees" an easier path to

ground over the deposits. This short circuit prevents normal

voltage buildup. The Booster Gap, however, isolates the coil

from the fouling deposits, allowing near normal voltage build-

up. The instant the Booster Gap sparks, sufficient voltage

appears across the firing gap and normal ignition results.

When you remove a plug wire from a fouled plug and let the

spark jump from the cable to the plug terminal to make the

plug fire, you are using this same Booster Gap principle.

Where are Booster Gap plugs used?

Maximum benefit from this design is obtained in

engines that operate over a wide load and speed range. For

example, a heat range cool enough for highway service will

have better fouling protection during stop-start city delivery

service with the Booster Gap.

Furthermore, the Booster Gap has been instrumental in

reducing the complaints of "break-in fouling" in new engines.

In many cases misfire due to oil fouling in older

engines can be relieved simply by using the recommended

heat range plug incorporating a Booster Gap.

A cure-all?

Not

at

all.

Booster

Gap

plugs

used

where

recommended and applicable to help solve fouling problems

will give excellent results. However, the need for the correct

selection of plugs in the proper heat range based on type of

vehicle operation is important.

Where more severe conditions of fouling as a result of

light service application or break-in fouling on engines occurs,

the alternate recommended hotter type plug with Booster Gap

should be used.

Voltage Requirements

While nominal in amount, the Booster Gap does

require more voltage initially than conventional spark plugs.

This higher requirement diminishes, however, after several

thousand miles of use.

Most any ignition system has more than adequate

reserve to supply the bit of extra voltage requirement; if you

experience misfiring with Booster Gap plugs and not with

conventional plugs, chances are the ignition system is

marginal.

It should also be pointed out that Booster Gap plugs

are not resistor plugs. If radio interference is a problem on

older vehicles having nonresistor ignition cables, it may be

necessary to install resistance leads (cables). Booster Gap

plugs may be used in conjunction with resistance-type ignition

cables to obtain interference suppression and still obtain the

added benefits of the Booster Gap. This is the combination

that is recommended on all gasoline powered motor truck

engines.

CTS-2016-J Page 8

PRINTED IN UNITED STATES OF AMERICA

|