|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

2.

Test for Spark at plug.

Disconnect high tension cable from one spark plug.

(always grasp spark plug boot and use a twisting

motion when removing plug cables so as not to

destroy resistance wire termination.) Insert extension

adaptor into boot and engage in cable terminal.

Using insulated pliers, hold plug cable to create

about 13 mm (1/2") gap between extension adapter

and engine (Figure 47). Have an assistant crank

engine. Observe for spark across gap.

Test at least two cables.

If spark occurs, ignition system is functioning. Check

spark plugs and ignition timing. Then look elsewhere

(engine condition, fuel system, etc.) for problem.

If no spark occurs, proceed to step 3.

Fig. 47 Checking for Spark at Plug

1. Battery

3. Ignition Coil

2. Ignition Switch

4. 13mm (1/2 in)Gap

3.

Test for spark at distributor cap. Disconnect high

tension

cable

from

center

tower

terminal

of

distributor cap. Insert extension adapter into boot

and engage in cable terminal. (Figure 44). Using

insulated pliers, hold cable to create about 13mm

(1/2") gap between cable terminal and engine (Figure

47). Have an assistant crank engine. Observe for

spark across gap.

If spark occurs, problem lies in distributor cap, rotor

or spark plug cables. (See Secondary Circuit

Inspection).

If no spark occurs, proceed to step 4.

Fig. 48 Checking for Spark at Distributor Cap

1. Battery

3. Ignition Coil

2. Ignition Switch

4. 13mm (1/2 in.) Gap

4.

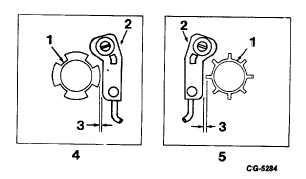

Check trigger wheel-to-sensor air gap

Remove distributor cap rotor and shield. "Bump"

starter to align one of the trigger wheel teeth with the

sensor coil (trigger wheel tooth perpendicular to flat

surface of sensor) as shown in Fig. 49. Check air

gap between trigger wheel tooth and sensor (see

SPECIFICATIONS). If air gap is to specifications,

proceed to step 5.

If air gap is out of specification, adjust air gap and

repeat step 3. If there is still no spark, proceed to

step 5.

Fig. 49 Trigger Wheel-to-Sensor Air Gap

1. Trigger Wheel

4. 4 Cylinder Engine

2. Sensor

5. 8 Cylinder Engine

3. Air Gap

CGES-145-U Page 24

PRINTED IN UNITED STATES OF AMERICA

|