|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

MECHANICAL ADVANCE SYSTEM SERVICE

Mechanical advance system components are not provided for

service individually. However, it is recommended that the

mechanical advance system be disassembled for inspection

and lubrication, as outlined below, at the time of distributor

overhaul.

Disassembly

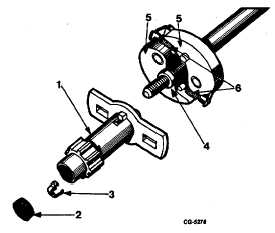

(Refer to Figure 37).

IMPORTANT

Mark Advance weights, weight pivot pins and

trigger wheel assembly to assure reassembly in

the same positions.

1.

Remove felt wick.

2.

Remove trigger wheel assembly retainer from

distributor shaft using hooked extractor tool.

NOTE: Do not remove trigger wheel from the

trigger wheel assembly, Figure 37.

3.

Slide trigger wheel assembly from distributor shaft.

4.

Remove primary and secondary advance weight

springs.

5.

Remove advance weights and thrust washer.

Fig. 37 Mechanical Advance System Components

1. Trigger wheel assembly

4. Thrust washer

2. Felt wick

5. Weights

3. Retainer

6. Springs

Inspect mechanical advance components. If wear or

damage is found, replace distributor shaft assembly.

Reassembly

1.

Lubricate advance weight bushings and pivot pins

with a light film of premium quality grease (Mobile

No. 532 or equivalent). Install weights on pivot pins.

2.

Install advance springs.

3.

Make sure advance weights pivot freely on pins.

4.

Lubricate trigger wheel assembly pilot surface of

distributor

shaft

with

premium

quality

grease.

Grooves in pilot diameter should be filled with

lubricant. Lands between grooves should have only

a thin film of lubricant.

5.

Apply a light coat of premium quality grease to thrust

washer and position thrust washer on distributor

shaft.

6.

Position trigger wheel assembly on pilot surface of

distributor shaft. Align slots in trigger wheel yoke with

pins on advance weights and push trigger wheel

assembly into position.

7.

Install trigger wheel assembly retainer. If necessary

bend arms of retainer to assure that retainer grips

slow in distributor shaft.

8.

Install felt wick.

9.

Make sure mechanical advance mechanism operates

freely.

TACHOMETER DRIVE SERVICE

Tachometer Drive Gear and Bearing Replacement

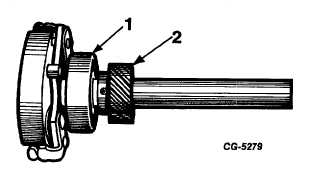

Tachometer drive gear and bearing (Figure 38) can

be replaced by following the procedure outlined below.

Fig. 38 Tachometer Drive Gear and Bearing

1. Bearing

2. Tachometer drive gear

CGES-145-U Page 17

PRINTED IN UNITED STATES OF AMERICA

|