|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

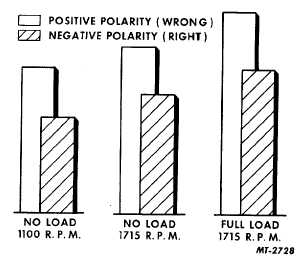

Fig. 5 Chart Showing Extra Voltage Required When Polarity Is

Reversed

For a time, the engine may run fine with coil polarity

reversed--until the spark plugs have been in use for some

time. Then, the driver may encounter hard starting or

misfiring under load, as the amount of voltage required to fire

the spark plugs under these conditions is higher than at any

other time.

In view of the above, it is very important that coil

polarity should always be such that negative current is

supplied to the spark plug terminals.

CHECKING FOR REVERSED POLARITY

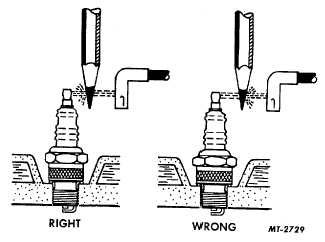

A quick and easy method in checking for reversed

polarity is the use of an ordinary wooden pencil, Fig. 6. Using

the wooden pencil-check method, remove an ignition cable

from any one of the spark plugs. Then, place the graphite tip

of the pencil between the spark plug terminal and the cable

and observe the spark as it jumps across the gap. If you

notice the spark flaring or having an orange tinge on the spark

plug side of the pencil, polarity is correct. If it flares or has a

tinge on the cable side, polarity is reversed (be sure to use a

wooden pencil when making this check or an uncomfortable

shock may be received from the spark plugs). NOTE: The

above check is used particularly on those coils not having any

markings on the coil terminals. All coils recommended and

used by the International Harvester Company are properly

marked.

NOTE: When checking for reversed polarity, always be

certain that the spark plugs are correctly gapped and in good

condition.

Fig. 6 Method of Checking for Reversed Polarity

CONDENSERS

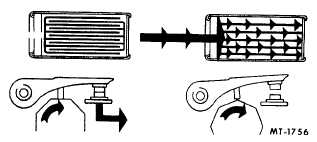

The condenser which is mounted inside ignition system

distributor prevents arcing of distributor points when points

begin to open by providing a place for current to flow until

points are safely separated. This requires special insulating

between the two foil sheets which store current flow and bring

it to a quick controlled stop, Fig. 7.

Fig. 7 Action of Current on Condenser

Ignition failures of a few years back were often the

result of condenser breakdown. Subsequent investigation

proved that internal moisture was responsible. With the

adoption of pre-dried insulating paper and hermetic sealing in

recent years, condenser breakdown has been practically

eliminated. Condenser can is crimped against outer gasket

and this compresses a spring at bottom of can with 40 pounds

pressure to effectively seal inner and outer gasket surfaces,

Fig. 8. Pressure feature provides vibration-free connections

which lessen the possibility of high series resistance in

condenser assembly.

CTS-2013-E Page 6

PRINTED IN UNITED STATES OF AMERICA

|