|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

TABLE 2

Specific

State of

Freezing

Gravity

Charge

Point

1.265

100%

-59.50 C (-75° F)

1.225

75%

-37.2° C (-35° F)

1.190

50%

-26.10 C (-15° F)

1.155

25%

-15.00 C ( +5° F)

1.120

Discharged

-9.40 C (+15° F)

Batteries must be kept fully charged when batteries or

vehicles are stored in sub-freezing temperatures.

TEMPERATURE AFFECTS BATTERY OUTPUT

CAPACITY (CRANKING POWER)

Battery temperature affects the output capacity of a battery

with respect to cranking an engine. The cranking power of the

battery is reduced as battery temperature is lowered.

Table 3 lists the approximate percentage of output capacity of

a fully charged battery at various temperatures.

Note that a fully charged battery at -17.8° C (0° F) gives only

40 percent of its cranking power at 26.7° C (80° F).

TABLE 3

Temperature

Percentage of Battery

Capacity

(Fully Charged)

26.7 C (80 F)

100%

0 C (32 F)

65%

-17.8° C ( 0° F)

40%

-28.8 C (-20°

F)

20%

Batteries at less than the fully charged

state will provide even less of their output

capacity. This emphasizes the importance

of keeping vehicle batteries fully charged

when low temperatures will be

encountered.

MAINTENANCE (IN VEHICLE)

The battery is a perishable item and requires attention. With

a reasonable amount of care the life of a battery can be

appreciably extended. Neglect and abuse will invariably

cause shorter battery service life.

The battery should be inspected at the time of chassis

lubrication or other periodic services.

Battery maintenance includes the following:

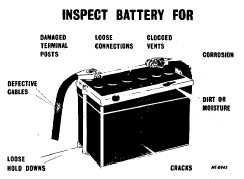

1. Inspect battery and mounting for defective cables, loose

connections, loose or damaged hold down parts, damaged

terminal posts or studs, clogged vents, cracked, or

distorted battery case or cover, and accumulations of dirt,

moisture and corrosion (Figure 8). Replace any damaged

parts.

Fig. 8 Battery Maintenance Inspection

2. If corrosion is found on the terminal posts, remove the

cable terminals from the battery (ground cable first) using

the proper end wrench and a cable puller. A terminal

cleaning brush can be used to clean tapered posts and

the mating surfaces of the cable clamps. Other type

terminals can be cleaned with a wire brush. The cable

terminals should then be cleaned with an acid neutralizing

solution of baking soda and water. Clean dirt from the

battery top with a cloth wetted with baking soda and

water. Then wipe with a cloth with clear water. A wire

brush can be used to remove dirt, corrosion or rust from

the battery tray or hold down parts.

After rust is removed, rinse with clear water dry with air

and repaint.

CTS-2771 Page 8

PRINTED IN UNITED STATES OF AMERICA

|