|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

COOLING SYSTEM

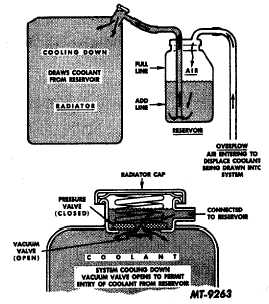

Fig. 6 System Cooling Down

For special filling of this type cooling system, refer to

MAINTENANCE Section in this manual.

B. ENGINE WATER JACKET

The water jacket permits coolant to be circulated around

the cylinder walls, combustion chamber and valve assemblies.

Some of the coolant passages are small and can become

clogged if the cooling system does not receive the proper

maintenance.

Close inspection should be given to the following areas:

1.

Core Plugs-These are sometimes mistakenly termed

"freeze plugs". The plugs are present due to engine

block casting methods and not to protect against

expansion from freezing. Core plugs that show signs

of leaking or rusting through should be replaced. Refer

to respective Engine Manual for core plug replacement.

2.

Drain Plugs-The drain plugs located in the water jacket

should receive seasonal care and kept free of rust and

scale.

3.

Gaskets-Must be in good condition to prevent both

internal and external leaks. If there are external leaks

around gaskets, there may also be internal leaks into

the engine. Proper tightening of the head bolts with a

torque wrench is essential for preventing leaks around

the head gasket.

C. WATER PUMP

The water pump circulates the coolant through the

cooling system. It should be checked carefully for leaks and

proper lubrication and if leaking or in bad condition, it should be

rebuilt or replaced promptly. For water pump rebuild, refer to

respective Engine Manual.

D. FAN AND BELTS

The fan should be checked for loose or bent blades. A

loose blade could work free during operation and cause

damage. A bent blade will reduce the fan's efficiency.

Fan belts must be adjusted for proper tension. Refer to

respecting Engine Manual or Operator's Manual for proper belt

tension.

E. THERMOSTAT

Thermostats provide a means of retarding or restricting

the circulation of coolant during engine warm-up. An

inoperative thermostat can cause engine overheating and a

subsequent loss of coolant. Thermostats can be tested by

submerging in hot water and noting the opening and closing

temperature. Use an accurate high temperature thermometer

for making this test. Refer to Engine Manual for proper opening

and closing temperatures.

F. HOSES AND CLAMPS

Hoses and clamps should be checked regularly as they

are often the source of hidden trouble. Hoses may appear in

good condition on the outside but the inside may be partially

deteriorated. If there are any doubts about a hose doing its job,

replacement should be made. Clamps should be inspected to

ensure they are strong enough to hold a tight connection.

G. TRANSMISSION OIL COOLER

On some trucks equipped with automatic or semi-

automatic transmissions, the transmission oil is circulated

through an oil cooler or heat exchanger. The function of this

unit is to control transmission temperature and thereby keep oil

in the proper temperature range for its most efficient lubrication.

This is accomplished by using engine heat to bring

transmission temperature up or by using the cooling system to

dissipate any excessive heat generated within the transmission.

Leakage due to corrosion or an improper seal will cause

contamination between the cooling system and transmission.

CTS-2019P Page 7

PRINTED IN UNITED STATES OF AMERICA

|