|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

4.

Check cup clearance of compensating port by

watching for surge of fluid in reservoir when pedal is

depressed.

5.

Internal wear or leaks are indicated by pedal fading

away under steady foot pressure (also sign of leak

elsewhere in system).

6.

To check residual check valve operation, depress

and release brake pedal. Open bleeder valve and

check for spurt of fluid indicating pressure in lines.

STOP LIGHT SWITCH

If stop lights are inoperative, it would indicate either

defective bulbs, defective switch, loose or broken connections

or switch improperly positioned.

BRAKE LINES, FITTINGS AND HOSES

1.

Check lines for kinks, dents or rupture.

2.

Check hoses for abrasion, kinks, soft spots, rupture,

collapse, cracks, twists or loose frame supports.

3.

Examine all connections for leaks.

4.

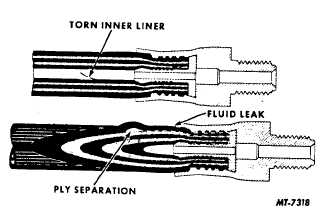

Carefully check for incomplete ruptures indicated by

a bubble between the plys of the flexible hose or a

torn inner line (Fig. 1).

Fig. 1. Flexible Hose Damage

5.

Brake line fittings will sometimes become rusted or

corroded to the wheel cylinder and/or brake line. Be

careful not to twist the line causing a line fracture

during removal or installation. Brake line open ends

should be capped to prevent the entrance of foreign

material.

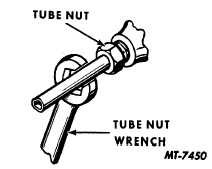

Fig. 2. Use of Tube Nut Wrench

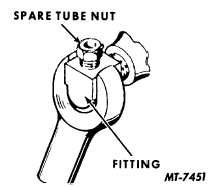

Fig. 3. Protecting Fitting Against Damage During Removal or

Installation

Always use correct type and size of wrench on

fittings (Fig. 2).

Avoid damage to female fittings by supporting fitting

with a spare tube nut during removal or installation

(Fig. 3).

6.

Use only steel tubing when replacement is required.

Use old tubing as a pattern for forming and routing

the new. Avoid kinks and sharp bends when forming

tube. Use tubing cutter to cut tubing to required

length making allowance for flare at each end of the

tube.

Assemble tube nuts on tubing before flaring. After

flaring tube, blow out with air pressure to remove any

particles of dirt or chips.

Do not discard old tube nuts until you are certain that

new ones are available.

WHEEL CYLINDERS

Pull back rubber boots and check for leaks. If

cylinders are disassembled, look for dirt, corrosion or pitting.

CTS-2055S Chapter 1 Page 4

PRINTED IN UNITED STATES OF AMERICA

|