|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BODIES AND CABS

Fig. 13 Repaired Hood and Fender Assembly.

REPAIRING SHEET METAL WITH FIBERGLASS

Small Holes (Under 3" Diameter):

Repair on sheet metal as well as fiberglass can be

made with the fiberglass reinforced plastic repair kit. It

can be used to repair torn holes, rust holes and

damaged surfaces which are difficult to refinish with the

usual sheet metal repair procedures.

1.

Clean metal to bare surface with No. 16 or 24 grit

sandpaper approximately 6" beyond area being

repaired.

2. Indent area being repaired about 2" beyond damaged

area.

3.

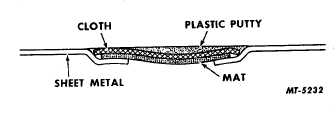

Cut a piece of mat about 1" larger than the surface

being repaired, then a piece of cloth (two or three

pieces of mat may be used to fill the indented area).

4.

Brush the resin mixture on the damaged area and

then saturate the layers of mat and cloth being used.

Allow the resin mixture to get tacky.

5.

Apply the mat and cloth patches, pressing the

laminations down tightly with a sheet of polyethylene

to produce a tight bond. (The cloth patch is installed

last). See Fig. 14.

Fig. 14

6. Allow material to cure.

7.

Sand and file surface after patches have cured.

8.

Mix up a plastic putty mixture and fill low areas.

9. Allow the putty to cure, then sand smooth.

Large Holes (Over 3" Diameter):

1.

Clean metal to bare surface and dent in surface

being repaired as in items 1 and 2 for "Small Holes".

2.

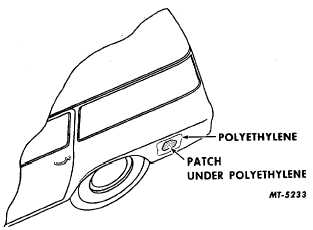

On a piece of polyethylene position a piece of cloth

larger than hole being repaired. Saturate with resin

mixture. Apply two layers of mat (Fig. 4) saturating

both with the resin mixture. Now place the entire

patch on the prepared surface and press on to metal.

See Fig. 15. Allow the patch to cure, then peel off

polyethylene.

Fig. 15

3.

In the resulting low spots, apply plastic putty. Then

over the putty position another sheet of polyethylene

and squeeze well to remove all air. When putty has

cured, remove polyethylene and sand down to a

feather edge.

Dents:

1. Clean metal to bare surface.

2. Drill or punch 1/8" holes in the dent to assure a good

anchor for patch. See Fig. 16.

3. If the dent is over 1", cover dent with piece of cloth and

saturate with resin mixture. Allow to cure.

CTS-2408 Page 7

PRINTED IN UNITED STATES OF AMERICA

|