|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

AXLE-FRONT

OPERATION

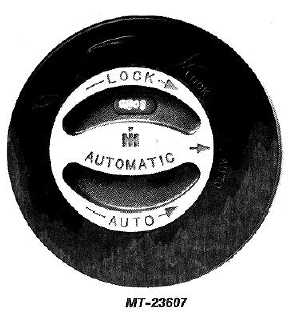

The automatic hub, when set in the "AUTO" position,

automatically locks the front wheel and axle shaft together the

moment torque is applied to the front axle. The hub controls,

therefore, do not require changing regardless of whether the

vehicle is being operated in two or four-wheel drive. It is

necessary, however, to set the control in the "LOCK" position

when engine braking control is required (down steep hills, on

ice, etc.).

Fig. 2. Dial Control

DO NOT DRIVE unless controls on both hubs are set properly

and both are set the same!

For the first 320 km (200 miles) operate your new vehicle with

the automatic hubs in "LOCK" position to assist in initial

break-in of the front driving axle. Place transfer case control

in 2-wheel drive position.

Always shift transfer case to 2WH before attempting to

disengage the locking hubs.

This will help to eliminate drive line wrap up which results

from 4W drive operation. Also, this will allow automatic hub

to disengage by rotating the control dial.

IMPORTANT

Torque wind up may be relieved by turning

hard right or left and backing up a short

distance while pushing the transfer case lever

into 2WD.

LUBRICATION

When reassembling the locking hub, lubricate as follows:

Lubricate dial, seals, splines, threads, rollers, cage, centering

spring and body with IH 251 HEP grease.

Fill

area

between

and

around

friction

shoes

with

approximately two tablespoons of grease. All remaining

surfaces require only a light coating. Excessive grease can

create malfunction of hub.

SERVICING

This locking hub is serviced in two major assemblies, namely,

a clutch half and body half. Since all individual components

are not provided, refer to the Scout Parts Catalog when

ordering.

To disassemble:

1.

Bend lock tabs out of way.

2.

Remove six (6) bolts.

3.

Remove cap assy.

4.

Remove snap ring from axle shaft.

5.

Remove body assy.

To reassemble:

1.

Clean gasket surface.

2.

Reverse disassembly procedure using new gasket

and lock tabs.

TORQUE SPECIFICATION

Torque hub assembly mounting bolts to 32-40 ft. Ibs. 43-54

N-m.

CTS-2785 CHAPTER I Page 3

PRINTED IN UNITED STATES OF AMERICA

|