|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

AXLES-FRONT

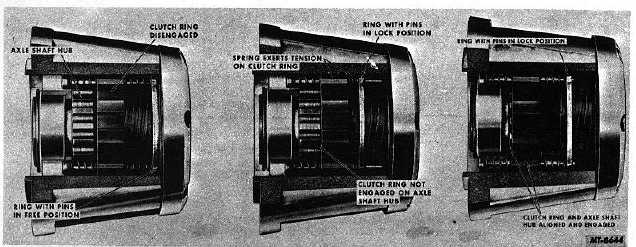

Fig. 5. Three Stage Operation of Spring Loaded Manual Locking Hub

A later version of the manual type locking chub is the spring-

loaded type, Fig. 5, which is designed to aid in the

engagement or disengagement of the front wheels with the

axles. These hubs overcome the need of moving the vehicle

slightly when the clutch ring does not mesh properly with the

axle shaft hub.

This spring in these new hubs permits the control to be

positioned in the desired location, and the slight movement of

the vehicle will allow the clutch ring to move into "LOCK" or

"FREE" position as selected on the control.

Lock- O- Matic Type

The Lock-O-Matic hub, when set in the "FREE" position,

automatically locks the front wheel and axle shaft together the

moment torque is applied to the front axle. The hub controls,

therefore, do not require changing regardless of whether the

vehicle is being operated in two or four-wheel drive. It is

necessary, however, to set the control in the "LOCK" position

when engine braking control is required (down steep hills, on

ice, etc. ).

OPERATION

Engaging Locking Hubs

To engage locking hubs, turn brass controls (one on each

hub) clockwise to "LOCK" position, Figs. 1 and 3. Arrow in

center of controls must point directly at dot located on rim of

hub. You can feel the brass control "seat" itself when it is

properly positioned. If the arrow does not point directly at the

dot, the control will not seat itself. Thus, the gears will not

completely engage, and the pressure may force off the end of

the hub. This is only true of hubs that are not spring loaded.

Hubs that are spring loaded allow the control to be positioned

in the engaged location, but engagement of the clutch ring on

the axle shaft hub is not accomplished due to misalignment of

components. Then when the vehicle is moved slightly, the

spring-loaded clutch ring will engage with the axle shaft hub,

Fig. 5 Right.

Disengaging Locking Hubs

To

disengage

locking

hubs,

turn

brass

controls

counterclockwise to "FREE" position, Figs. 2 and 4. Here,

again, the arrow must point directly at the dot on the rim,

otherwise the gears may rake against each other.

The hub on the left side in Fig. 5 illustrates the spring-loaded

type locking hub in the "FREE" position.

When controls are properly positioned, gears are completely

engaged or disengaged and units will not be damaged.

The following CAUTION hints may prevent damage to the

locking hubs:

1.

Use fingers only to turn controls. If control's do not

move freely with your fingers, move vehicle slightly in

either direction in two-wheel drive, standard gear

range. If hubs do not now turn freely, look for

external damage or dirt around brass controls. DO

NOT force controls with tools.

2.

DO NOT drive vehicle unless controls on both hubs

are properly positioned and both are set the same.

CTS-2209 Page 3

PRINTED IN UNITED STATES OF AMERICA

|