|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

WHEELS, RIMS, TIRES

Stud Corrosion

While this problem is not too common, it can occur and

make it difficult to obtain accurate' torque checks. When

corroded studs are encountered thorough wire brushing is

necessary. If corrosion is excessive, stud replacement is

recommended. If corrosion is persistent and a definite

problem is encountered with the cap nut freezing, the

lubrication of the first three threads of the stud with a graphite

base lubricant will solve this problem. Care must be taken to

assure that no lubricant gets in the ball seats of the stud holes

or in the ball faces of the cap nuts. Clean, dry cap nut faces

and nut seats at the wheels is necessary to maintain tight nuts

to specified torque. DO NOT OIL nut or stud threads except

as stated above.

Worn Stud Grooves

This is a result of improper initial assembly of the stud,

or from insufficiently tightened cap nuts. Either of these

conditions allow the shoulder of the stud to work in the groove

and eventually wear the groove until the stud will not hold,

Fig. 8.

Fig. 8

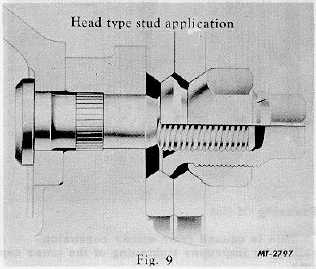

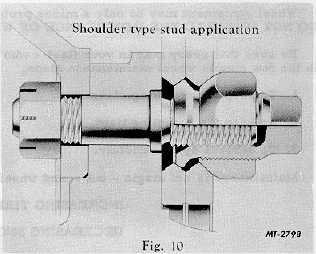

Use Of Correct Studs

When it is necessary to replace studs in a hub, it is

very important that the correct stud is used. Fig. 9 and 10

illustrate the correct stud application.

Fig. 9

Fig. 10

CAP NUTS

Worn Ball Faces

This is a result of operating on a loose wheel assembly,

Fig. 11.

CTS-2167N Page 5

PRINTED IN UNITED STATES OF AMER ICA

|