|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

WHEELS, RIMS, TIRES

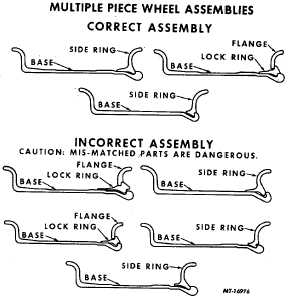

Multiple Piece Rims

On multiple piece rims if it is determined during

periodic inspection or during tire changes, that a part is

defective it must be replaced.

Caution must be observed when selecting the proper

replacement part, an incorrect fit is dangerous. (See Incorrect

Assembly Fig. 5). The side ring, locking ring and base must

all fit correctly as illustrated in Figure 5 under Correct

Assembly.

MULTIPLE PIECE WHEEL ASSEMBLIES

CORRECT ASSEMBLY

Fig. 5

ALUMINUM WHEELS

Care and Maintenance

Aluminum wheels should be periodically inspected both

on the vehicle and during tire changes for cracks, loose wheel

studs, worn mounting holes or being bent.

When checking cap nuts on dual disc wheels, back off

outer nut before attempting to tighten inner nut.

Whenever a tire is removed, clean off all grease and

road dirt. Use a wire brush or steel wool to remove the rubber

from the bead seat.

Projections on the side wall of the gutter may cause

uneven seating of the side ring and lead to chipping of the

gutter. Remove these and other projections in the mounting

area to assure the best possible fits.

Nicks and gouges in the vicinity of the fixed flange may

lead to rim fracture.

NOTE: Do not heat or weld wheels in an attempt to

straighten or repair severe road damage. The special alloy

used in these wheels is heat-treated, and uncontrolled heating

from welding torch affects the properties of the material.

To avoid possible corrosive affects to aluminum

wheels, use only a slight amount of water and neutral soap

(similar to Ivory Snow, Dreft, etc. no detergents) when

mounting tires. Do not use commercial rubber lubricants.

Wheel Installation

When installing aluminum wheels, lubricate stud

threads using a petroleum base grease containing colloidal

graphite. Be certain end of wheel wrench is smooth as it will

tear grooves in the wheel around the stud nuts it if is rough.

NOTE: Do not allow dirt to enter the mounting area

during installation. See "TORQUE CHART" for correct torque

values.

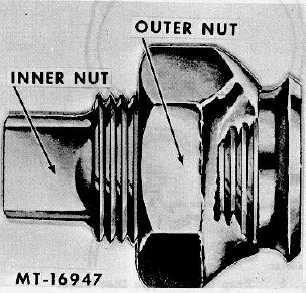

Wheel Studs and Mounting Nuts

Maintaining wheel stud and mounting nut tightness

does much to insure safe and satisfactory wheel operation.

Loose wheel mounting can cause vibration, shimmy, tire

wear, stud breakage, worn studs, mounting nuts (Fig. 6) and

worn or elongated stud holes (Fig. 7). Parts with these

characteristics must be replaced. Always keep wheel stud

nuts tightened to specified torque.

Fig. 6

CTS-2032N Page 2

PRINTED IN UNITED STATES OF AMERICA

|