|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

TRANSMISSION

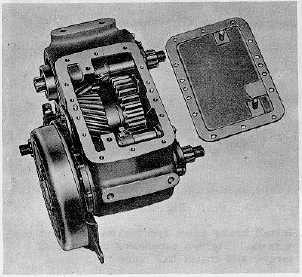

Fig. 42.

41. Slide range shift shaft through fork. Install set screw,

tighten and lock wire to shift fork (Fig. 42).

42. Install expansion plugs at rear of case and flatten to

expand.

43. Place detent balls and springs in position in case.

44. Install cover with a new gasket and tighten capscrews to

specified torque.

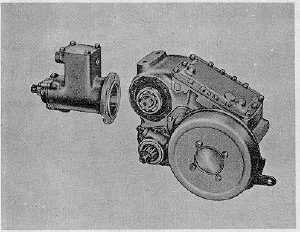

45. Install power-take-off assembly over a new gasket (Fig.

43). Secure with capscrews and lockwashers.

Fig. 43.

46. Install yokes or flanges and nuts and tighten to specified

torque.

LUBRICATION

Install drain plug and tighten. Turn unit upright and pour

.47 liter (1/2 pint) of recommended gear lubricant through the

filter plug opening. Add some oil to the power-take-off. Do not

fill the unit to specified level until it is installed under the

vehicle.

Refer to LUBRICATION, Section CTS-2412 for type of

lubricants recommended.

Lubricant capacity is 3.08 liters (6-1/2 pints).

OPERATION TEST'S

Shift Test (With power-take-off and front axle declutched

disengaged).

1.

High Range: Move range shift shaft to the rearmost

position (so the sliding gear engages direct drive

gear); turning input shaft should also turn output to

the rear axle.

2.

Low Range: Move range shift shaft to forwardmost

position (so the sliding gear disengages direct drive

gear); turning input shaft should also turn output to

the rear axle.

3.

Neutral: Move range shift shaft to intermediate

position between Hi and Lo; turning input shaft

should not turn output to rear axle.

Power-Take-Off

Engaged: Move shift shaft to forwardmost position to

engage the PTO: turning input shaft should also turn the PTO

shaft.

Front Axle Declutch:

Engaged: Move declutch shift shaft to rearmost position;

turning input shaft should also turn output to front axle.

CTS-2048Q Page 14

PRINTED IN UNITED STATES OF AMERICA

|