|

| |

TM5-4210-229-14&P

6-15.

TRANSMISSION REPAIR (Continued).

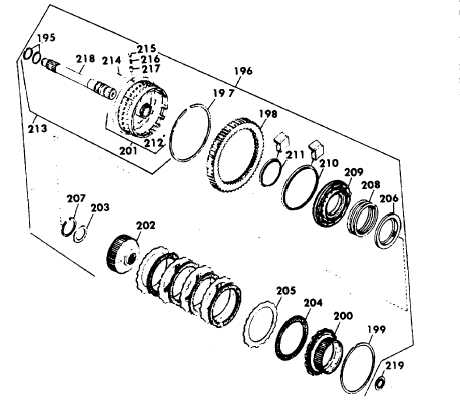

(h) Hold the fourth clutch driving hub (200)

firmly against the snapring and, using

forward clutch clearance gauge check the

clearance between the fourth clutch driving

hub (200) and the internal-splined clutch

plate (204). The prescribed clearance for

the forward clutch is 0.079-0.130 inch

(2.01-3.30

mm).

When

clearance

is

achieved, the first step of clearance gauge

will fit between the hub and plate; the

second step will not.

(i) If the clearance is excessive (second step

of gauge fits), replace the thinner clutch

plates with new plates. If the clearance is

still excessive after all ten plates and

fourth clutch drive hub (200) have been

replaced, a thicker piston (209) is required.

(j) If the clearance is insufficient (first step of

gauge will not fit), a thinner piston (209) is

required.

(k) Remove the snapring (199) that retains the

fourth clutch driving hub (200) and remove

the hub (200). Remove the forward clutch

plates (204 and 205).

CAUTION

If either piston sealring (210 or 211) is

installed incorrectly, the forward clutch will

not operate properly.

(I) Lubricate and install the piston sealrings

(210 and 211) into their grooves in the

housing hub (201) and piston (209). Make

sure the sealring lips face toward the oil

pressure side of the piston. Install the

piston (209) into the housing.

(m) Place the clutch housing and shaft

assembly, and assembled piston on a

press bed. Install the piston return spring

(208) and spring retainer (206) and position

the snapring (207) on the hub. Using

compressor

tool,

depress

the

spring

retainer (206) sufficiently to install the

snapring (207) into its groove in the

housing hub.

6-68

|