|

| |

TM5-4210-229-14&P

6-15.

TRANSMISSION REPAIR (Continued).

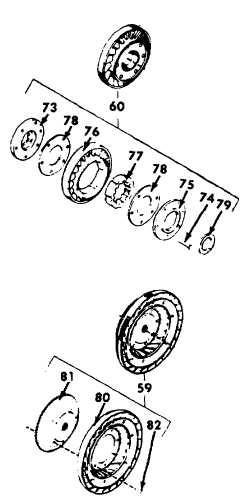

(m) Place the stator assembly (60) on fixture

stand.

Install

staking

tool

into

the

fixturehead and tighten the thumb screw

finger tight.

(n) Apply approximately 800 pound (3629 kg)

load to swage each rivet head. Swage the

second rivet 180 degrees from the first.

Locate the third rivet, 60 degrees from the

second and swage it. Locate the fourth

rivet 180 degrees from the third, etc., until

all rivets are swaged.

(o) Remove the retaining bolt, top plate, base

plate and staking tool. Install new needle

bearing (79) referring to paragraphs a. (2)

(o) through a. (2) (r) above.

(4) Converter turbine repair.

NOTE

Do not disassemble the turbine unless

the turbine hub must be replaced. If the

converter turbine is damaged, replace

the assembly (59).

A hydraulic press having a minimum

capacity of ten tons (9,070 kg), an

adjustable press bed with a 25 inch (635

mm) opening and a pressure gauge to

assist in determining the rivet swaging

load, are required to repair the turbine

assembly (59).

(a) Punch alignment marks on the turbine (80)

and turbine hub (81) to show their

relationship.

(b) Place base plate on a work table, rivet hole

side up.

(c) Place converter turbine assembly (59)

front side upward (turbine vanes down), on

top of the base plate. Align the eight rivets

(82) in the hub to the holes in the base

plate.

(d) Place guide plate on top of converter

turbine assembly (59). Centrally locate

each rivet (82) in the guide plate holes.

(e) Install the 1/2-13x3-1/2 inch clamping bolt

to retain the guide plate, turbine and base

plate together. Torque the bolt 50 ft-lb (68

N.m).

(f) Place the turbine assembly and fixture in

the drill press.

CAUTION

Do not use a hammer to remove the

rivets, damage to turbine assembly may

result.

(g) Place drill bushing into guide plate. Using a

1/4 inch drill, drill approximately 3/16 inch

deep into the rivet.

6-52

|