|

| |

TM5-4210-229-14&P

6-15.

TRANSMISSION REPAIR (Continued).

Cleaning solvent (Appendix D, Item 54) is

both toxic and flammable. Keep off skin.

Use only in a well-ventilated area and

avoid prolonged breathing of vapors.

Keep away from open flames.

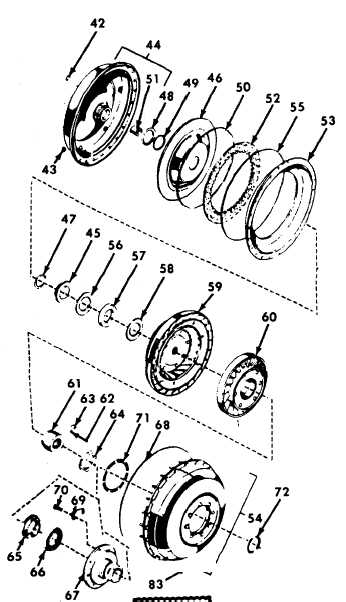

(n) Check needle bearing assembly (64).

Wash and flush the needle bearing

assembly thoroughly with cleaning solvent

(Appendix D, Item 54). Dry it, and lubricate

with transmission oil (Appendix D, Item

38). Replace the freewheel race only and

rotate the bearing while pressing upon the

freewheel race. If there is no roughness or

binding, the needle bearing assembly may

be left in the stator and cam assembly and

reused. Do not mistake dirt or grit for a

damaged needle bearing. Reclean and

reoil the needle bearing if dirt is suspected.

Check the needle bearing end of freewheel

race for smooth finish. Replace the

freewheel race if the bearing end is

scratched or contains chatter marks.

NOTE

If it is necessary to repair the stator

assembly (60), remove needle bearing

assembly (64) before starting repair

procedure.

(o) If needle bearing assembly (64) needs

replacement, follow steps (p) through (r)

below.

CAUTION

Do not scratch or nick any stator bores.

Do not attempt to disassemble the

stator and cam assembly, unless part

replacement is necessary.

(p) If the needle bearing must be replaced,

remove it carefully to avoid nicking the

aluminum bore in which it is held.

(q) Place a new bearing assembly, thrust race

first, into the aluminum bore of the stator.

Using bearing installer, install the thrust

bearing.

CAUTION

Apply the load only to the outer shell of

the bearing during installation.

(r) Drive the bearing assembly into the stator

until the top of the outer shell is 0.025-

0.035 inch (0.64-0.89 mm) above the

shoulder in the side plate. The installing

tool will seat on the stator area surrounding

the bearing when the bearing is properly

installed.

(s) Remove needle bearing (64), bearing race

(65), and remove roller bearing (66) with

converter pump hub roller bearing remover

and installer from converter pump hub

(67). Remove sealring (68).

6-50

|