|

| |

TM5-4210-229-14&P

6-12. PISTON AND CONNECTING ROD MAINTENANCE (Continued).

Compressed air used for cleaning or drying

can create airborne particles that may enter

the eyes. Pressure shall not exceed 30 psi

(206 kPa). Wearing of goggles is required to

avoid injury to personnel.

(3) Dry the sleeves with compressed air.

(4) Clean and flush out the water jacket in the

crankcase.

(5) Measure the I.D. of the sleeve with an inside

micrometer or bore gauge from the top and

bottom of the sleeve where it is subjected to

piston and ring travel, and the O-ring area.

(a) Take measurements at right angles to

determine if the sleeve is out of round

or excessively tapered.

(b) Maximum permissible diameter sleeve

wear, at top of ring travel, before re-

placement is 0.004 in (0.10 mm).

(c) If sleeve does not meet specifications,

it must be replaced with a new sleeve

(and piston).

(6) Inspect the sleeve for scuffing or scoring.

Replace sleeve (and piston) if this condition

is found.

CAUTION

Do not hone the cylinder sleeves.

(7) Inspect counterbore for burrs or fractures,

replace if evident.

INSTALLATION

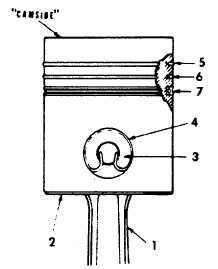

a. Connecting rods, pistons, and rings assembly.

(1) Install new connecting rod piston pin bush-

ing using a suitable arbor press. Bore or

hone the new bushing to 1.6256 to

1.6258 in. (41.2902 to 41.2953 mm) after

assembly.

(2) Generously coat the piston bore and piston

with molykote (Appendix D, Item 35).

(3) Insert the pin end of the connecting rod (1)

into the piston (2) aligning bored holes of

the rod and piston (the short side of the

split on the crank end of the rod is to be

toward the side of the piston marked cam-

side).

(4) Align the bushing in the rod with the piston

pin holes in the piston and push the piston

pin (3) completely into position. (Pin is a

loose fit at 70° F (21° C).)

(5) Squeeze the pronged ends of the piston pin

retainer rings (4) and install a ring in the

groove at each end of the piston to secure

- the piston pin.

(6) Using a piston ring expander, install the

rings into the grooves of the pistons.

(a) The compression rings (groove num-

bers 5 and 6) must be installed as direc-

ted by the word top, up or pip, mark

stamped on the edge. The tappered

face second compression rings must

have the witness mark (shiny part) to-

wards the bottom of the piston.

(b) The oil-regulating ring (groove number

7) can be installed with either face up.

6-33

|