|

| |

TM5-4210-229-14&P

6-12. PISTON AND CONNECTING ROD MAINTENANCE (Continued).

(5) Remove connecting rod piston pin bushing

using a suitable arbor press. Discard old

bushing.

INSPECTION

a. Connecting rod inspection

Cleaning solvent, (Appendix D, ,Item 54) is

both toxic and flammable. Keep off skin.

Use only in a well ventilated area and avoid

prolonged breathing of vapors. Keep away

from open flames.

(1) Using a cleaning solvent (Appendix D, Item

54) clean the threads and mating surfaces

between the rod and cap.

(2) Clean the oil hole at the top of the rod and

keep it unclogged.

(3) Clean all bolts thoroughly.

(4) Inspect all bolts for nicks or damage. When

lubricated, the bolts must screw into the

rod face by hand. If the bolt will not screw in

by hand, reclean the rod threads and try a

new bolt. If a new bolt does not screw in

freely, the rod must be discarded.

CAUTION

Do not retap rods as this is a special rolled

thread.

(5) When new bolts are used in a rod, they must

be torqued to 130 ft-lb (175 N.m), loosened,

and retorqued three times.

(6) Check the integrity of connecting rod bear-

ing bores for mis-match between cap and

the rod and for out-of-round. These checks

are only valid when the insert is omitted and

bolts are torqued to 130 ft-lb (175 N.m)

using lubricating oil (Appendix D, Item 37)

as a lubricant under the head of the bolt and

in the threads. An inside micrometer is re-

commended, but a dial bore gauge can be

used for measurements.

CAUTION

Lack of attention to the integrity of connecting

rod bearing bores during an overhaul may re-

sult in a rod bearing failure. Careful attention

must be given to all aspects of the rod and

bolts.

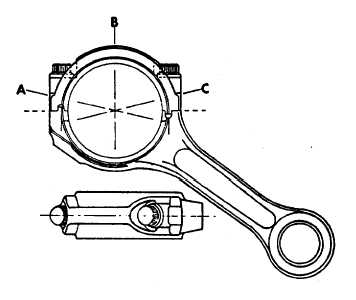

(7) Measure and record the three inside diam-

eters of each rod at points A, B, and C.

(8) If the difference between points A and C is

over 0.004 in. (0.10 mm), the mismatch is

excessive and the rod should be discar-

ded.

(9) If the difference between point B and the

average of A and C (A+ C divided by 2)

exceeds 0.002 in. (0.05 mm), the rod should

be discarded.

b. Running clearance and end clearance inspection.

CAUTION

Do not turn the crankshaft during the follow-

ing procedures.

6-30

|