|

| |

TM5-4210-229-14&P

6-11. OIL PUMP, FILTERS, AND COOLER MAINTENANCE (Continued).

CAUTION

Whenever the oil filter base is removed from the

crankcase, be careful not to mix the capscrews

with any other hardware. These special screws

are necessary to prevent oil leaks as one of the

bolt holes connects with an oil pressure gallery.

(4) Remove the filter base with the elements

attached.

(5) Remove base gasket.

c. Oil cooler removal.

(1) Remove four screws securing the cooler to

the crankcase.

(2) Remove the cooler by pulling towards the

rear of the engine.

INSPECTION

Compressed air used for cleaning or drying

can create airborne particles that may enter

the eyes. Pressure shall not exceed 30 psi

(206 kPa). Wearing of goggles is required to

avoid injury to personnel.

Cleaning solvent (Appendix D, Item 54) is both

toxic and flammable. Keep off skin. Use only

in a well-ventilated area and avoid prolonged

breathing of vapors. Keep away from open

flames.

a. Wash all parts with solvent (Appendix D, Item

54) and dry with compressed air.

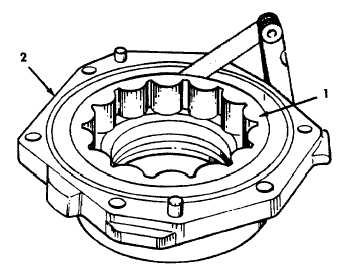

b. Visually inspect the oil pump rotors, housing,

and housing plate for nicks, burrs, and scoring.

CAUTION

The inner and outer rotors are a matched set

and cannot be replaced separately.

c. Check the radial clearance between the outer

rotor (1) and the pump housing (2) with a feeler

gauge. The limits 0.0055 to 0.0095 inch (0.140

to 0.241 mm) must be maintained.

6-24

WARNING

|