|

| |

TM5-4210-229-14&P

6-10. TIMING AND GEAR TRAIN MAINTENANCE (Continued).

b. Blow dry parts with compressed air.

c. Visually inspect all gears for wear or damaged

teeth. Replace any with evidence of damage.

d. Visually inspect bearings, spacer, and stub shaft

for wear or damage.

INSTALLATION

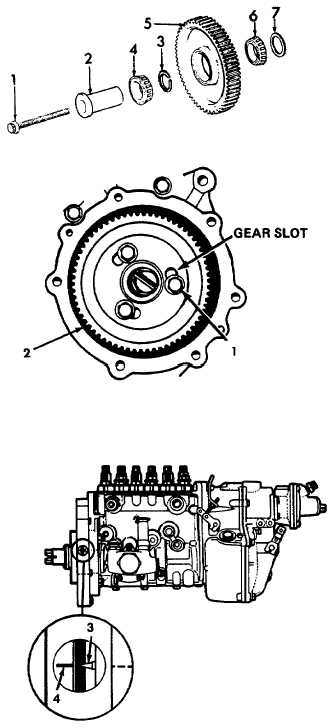

a. Idler gear installation.

(1) Assemble spacer (1), bearing (2), spacer

(3), bearing (4), and stub shaft (5) to idler

gear (6).

(2) Install assembled parts with the timing marks

facing out. Be sure the rear spacer (1) is in

position. A small amount of grease (Appen-

dix D, Item 21) will aid in holding the spacer.

(3) Install and torque the retaining bolt (7) to

85 ft-lbs (115 N.m).

b. Injection pump gear installation.

CAUTION

Be sure that engine crankshaft timing is set

at specified static timing prior to going any

further.

(1) Using drive gear bolts and washers (1),

loosely install injection pump drive gear (2)

to injection pump meshing it with idler gear.

Make sure drive gear is positioned in gear

slots so it allows for adjustments.

(2) Align timing pointer (3) with timing mark

(4) by rotating injection pump clockwise (as

viewed from drive gear end.)

(3) Holding the pump shaft with a socket wrench,

torque drive gear bolts to 35 ft-lb (47 N.m).

(4) Rotate engine crankshaft counterclockwise

until pump timing pointer and timing mark

align.

(5) Observe engine to injection pump timing on

crankshaft pulley. Timing sould be 23° ñ 1°.

c. Install camshaft and gear (paragraph 6-9).

6-22

|