|

| |

TM5-4210-229-14&P

6-9. CAMSHAFT AND GEAR MAINTENANCE (Continued).

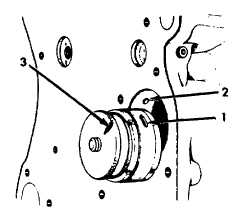

a. If the camshaft bushings were removed, install

new bushings using the camshaft bushing puller

and installer tool from the camshaft bearing ser-

vice set. Be sure the oil holes in the bushing (1)

line up with the oil holes in the crankcase (2).

b. To ease oil hole alignment, mark the back-up

nut (3) in line with the bushing oil hole (1) when

installing the bushings.

c. Camshaft gear replacement.

(1) The drive gear on the camshaft must be

pressed off since it is a shrink fit.

(2) Place the thrust plate on the keyway end of

the camshaft against the bearing journal.

(3) Insert the woodruff key into the keyway.

NOTE

Use a Thermomelt crayon to determine

temperature.

(4) Heat the camshaft gear to approximately 400° F

(205° C).

Wear asbestos gloves when installing gear.

(5) Press the gear against the shoulder on the

shaft with the timing mark pointed out-

ward.

d. Coat the cam lobes, bearings and journals with

clean engine oil (Appendix D, Item 37) and

install the camshaft.

e. Install the camshaft so that the timing marks

stamped on each gear are in line.

f. Alternately torque the thrust plate cap screws

to 20 ft-lb (27 N.m) torque.

g. Check the camshaft end play with a dial indicator.

End play should be 0.005 to 0.013 in (0.13 to

0.33 mm).

h. Install front cover (paragraph 6-8).

i. Install cylinder head and valves (paragraph 6-6).

6-10. TIMING AND GEAR TRAIN MAINTENANCE

This task cover: a. Removal

b. Inspection

c. Installation

INITIAL SET-UP

Tools

Dial Indicator

General Mechanics Tool Kit

Equipment Condition

Para. Condition Description

6-9 Camshaft and Gear Removed

Materials/Parts

Idler Gear (675764C1)

Injection Pump Drive Gear (1802737C1)

Cleaning Solvent (Appendix D, Item 54)

Grease (Appendix D, Item 21)

6-20

|