|

| |

TM5-4210-229-14&P

6-9. CAMSHAFT AND GEAR MAINTENANCE

This task cover: a. Removal

b. Inspection

c. Installation

INITIAL SET-UP

Tools

Dial Indicator

Camshaft Bearing Service Set (SE-2893)

General Mechanics Tool Kit

Micrometer

Press

Equipment Condition

Para.

Condition Description

6-6

Cylinder Head and Valves Removed

6-8

Front Cover Removed

REMOVAL

NOTE

Prior to removal, cam lobe lift can be

inspected with camshaft in engine by

using a dial indicator. Record the lift

readings of each lobe. Cam lobe lift shall

be 0.2935 inch (7.455 mm). If wear is 0.020

inch (.51 mm) or greater, replace the

camshaft.

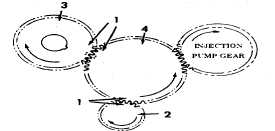

a. Crank engine until timing marks (1) on crank-

shaft gear (2), camshaft gear (3), and idler gear

(4) are in line.

NOTE

Before removing the camshaft gear (3),

check the camshaft end clearance 0.005 to

0.013 in (0.13 to 0.33 mm). If specification is

not met, new parts are required.

b. Rotate camshaft gear (3), and by reaching

through the holes in the gear, remove two cap-

screws securing camshaft thrust plate to crank-

case.

c. Remove camshaft. (Support camshaft along its

length, as it is being removed, to prevent cam

lobes from damaging bushings).

Materials/Parts

Cleaning Solvent (Appendix D, Item 54)

Camshaft (1802339C92)

Camshaft Gear (675600C1)

Bushings (680117C1)

Thermomelt Crayon (Appendix D, Item 54a)

INSPECTION

Cleaning solvent, (Appendix D, Item 54), is

both toxic and flammable. Keep off skin. Use

only in a well ventilated area and avoid pro-

longed breathing of vapors. Keep away from

open flames.

Compressed air used for cleaning or drying can

create airborne particles that may enter the

eyes. Pressure shall not exceed 30 psi

(206 kPa). Wearing of goggles is required to

avoid injury to personnel.

CAUTION

Do not damage the journals and lobes of the

camshaft, or the teeth of the gear.

a. Clean all parts in solvent (Appendix D, Item 54)

and dry with compressed air.

b. Visually inspect camshaft lobes for scuffs, scores,

or cracks.

c. Inspect the journals for wear. Using a

micrometer, measure the camshaft journal to

insure specifications of 2.2814 to 2.2825 in

(57.948 to 57.976 mm) are met. If the journals

are worn beyond these limits, replace the cam-

shaft.

d. Camshaft lobe wear check.

(1) Compare lifting areas of the cam lobes with

a new camshaft. If excessive wear is visible,

replace the camshaft

6-18

|