|

| |

TM 5-4210-229-14&P

6-6.

CYLINDER HEAD AND VALVES MAINTENANCE (Continued)

(b) Lightly polish valve surface with extremely

fine emery cloth (Appendix D, Item 13).

(2) Visually inspect each valve for excessive wear,

burn marks, warpage, pitting, or scuffing at valve

stem grooves, valve stems, or valve heads.

Replace valves which are seriously bent, worn,

burnt, warped, pitted, or scuffed.

INSTALLATION

a. Resurface

valve

face

angle,

if

necessary.

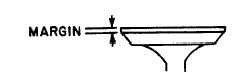

Maintain a minimum valve face margin of 0.068

in.(1.73 mm) for intake valves and 0.045 in.(1.14

mm) for exhaust valves.

b.

Set valve in grinder to desired angle.

c.

Dress the wheel to proper angle.

d.

Take a light cut off valve face angle surface.

e.

Replace valve if more than 0.008 in. (0.20 mm)

stock is removed from valve face angle or if

margin falls below minimum specifications.

f.

Check valve face run out, after resurfacing, with

dial indicator.

g.

Replace valve if run out (in reference to valve stem)

is greater than 0.002 in. (0.05 mm) total variation in

dial indicator reading.

h.

After resurfacing valves, clean valve guides and

check valve face contact with valve seat using

bluing ink (Appendix D, Item 23).

(1) Spread thin film of bluing ink (Appendix D,

Item 23) on valve face. Insert valve into

its guide.

(2) Apply pressure on exact center of valve head,

while making a quarter turn in the seat.

(3) Remove valve, inspect impression made on

seat and on valve face.

(4) Bluing ink (Appendix D, Item 23) should

appear around entire contact surface of valve

face and valve seat to be acceptable. Check several

times to prevent error. If acceptable, proceed with

valve installation.

NOTE

If bluing ink (Appendix D, Item 23) DOES NOT

show around the entire contact surface of the

valve seat, the angles do not match and are

unacceptable. If this happens, correct

resurfacing valve seats; not valve faces.

i.

Valve seat resurface.

(1) Dress the grinding wheel to correct angle.

lightly lubricate and install correct size pilot

into valve guide bore.

(2) Lower grinder head over pilot shank until

wheel barely clears the valve seat. Turn on

power. Gently apply grinding wheel to valve

seat with little pressure other than weight of

the wheel.

(3) Raise

wheel

frequently

to

prevent

overheating.

(4) Grind seat to a smooth even surface.

(5) Check seat concentricity, roundness and

valve

face

contact

using

bluing

ink

(Appendix D, Item 23) following installation

procedure h.(6) After grinding seats, it may

be found that seats are wider than the

specified width.(7) Correct wide valve seats

by grinding top edge of seat with a stone

mounted on grinder head. The stone must

be smaller angle (preferably 15 degrees)

than the valve seat.

NOTE

If

valve

does

not

seat

properly

after

resurfacing valve seats, replace valve seats.

6-10

|