|

| |

TM 5-4210-229-14&P

6-6.

CYLINDER HEAD AND VALVES MAINTENANCE (Continued).

NOTE

Sudden change in contour such as scratches,

gouges, etc. must not exceed 0.002 inches(0.05

mm) in depth.

(5)

Inspect nozzle sleeve bore for grease, oil, scale,

or rust after removing sleeve.

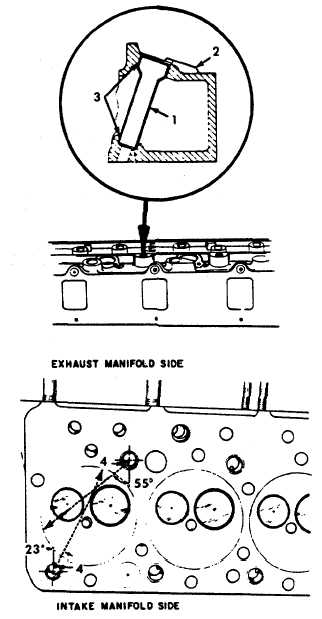

(a) Remove nozzle sleeve (1) from cylinder

head (2) by using a slide hammer and nozzle

sleeve puller adapter.

(b) Inspect and clean bore as necessary.

(c) After cleaning bore, apply loctite (Appendix

D, Item 27) to upper contact surface (3) of

sleeve (1).

(d) Place nozzle sleeve (1) into cylinder

head(2). Position nozzle sleeve installing

tool in sleeve. Keep tool centered and tap

squarely with brass hammer until sleeve is

bottomed in bore.

(6)

Inspect cylinder head coolant directors for

restrictions or looseness.

(a) Visually check for restrictions.

(b) Tap or pull directors by hand to check for

looseness.

(c) Remove loose or restricted coolant directors.

Use a slide hammer with a small enough jaw

to hook under coolant director (4) "opening."

(d) New coolant directors should be tapped into

place with a small hammer and block. They

must be recessed 0.06 inch (1.5 mm) below

the bottom deck of the cylinder head.

(e) Aim coolant directors at angles shown in

illustration.

b.

Valve guide inspection.

Failure to clean valve guide bore can cause

premature valve guide wear and in severe

conditions, valve breakage.

6-8

|