|

| |

TM 5-4210-229-14&P

6-6.

CYLINDER HEAD AND VALVES MAINTENANCE (Continued)

b

Valve removal.

Keep valves in order so reinstallation in

original valve guide is assured.

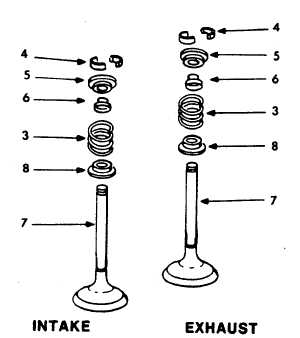

(1) Compress valve springs (3) using a spring

compressor tool.

(2) Remove spring retainer locks (4).

(3) Remove rotators (5) and oil shields (6).

(4) Allow valve (7) and valve seat (8) to drop out of

guide.

NOTE

If valve does not dropout, inspect valve stem

for burrs. If burr exists, remove with a hone to

prevent valve guide damage.

INSPECTION

a.

Cylinder head inspection.

(1) Remove deposits from upper and lower deck of

head. Pay special attention to exhaust valve

ports, valve seats, injection nozzle sleeves and

water directors.

Cleaning solvent (Appendix D, Item 54) is both

toxic and flammable. Keep off skin. Use only in

a well-ventilated area and avoid prolonged

breathing of vapors. Keep away from open

flames.

(a)

Use cleaning solvent (Appendix D, Item

54)and brass wire brush (Appendix D, Item 7)

to clean bores.

Compressed air used for cleaning or drying can

create airborne particles that may enter the eyes.

Pressure shall not exceed 30 psi 206 kPa).

Wearing of goggles is required to avoid injury to

personnel.

(b) Blow out carbon deposits with compressed air

after cleaning.

(2)

Visually inspect head for cracks using spraying

methods. If cracks are found, replace cylinder

head.

6-6

|