|

| |

TM5-4210-229-14&P

5-7.

RESCUE SAW REPAIR (Continued).

(1)

Inspect crankshaft (167) for cracks, breaks

and misalignment, and crankshaft threads and

bearing surfaces for wear, scratches, gouges

and flat areas.

(2)

Inspect needle bearing (168) for wear and

damage.

(3)

Inspect piston (154) for cracks, uneven wear

and damage to ring grooves, and piston pin

(153) for wear and looseness of fit.

e.

Rescue Saw Cylinder, Crankcase and Muffler

Inspection.

(1)

Inspect cylinder (150) and crankcase (175)

and 172) for broken or cracked pins, warped

head mounting surfaces, worn or scored

bearings, distorted or worn threads.

(2)

Inspect cylinder cooling fins for cracks or

breaks.

(3)

Inspect clutch (96) for bearings and springs

that are worn, scored, damaged, cracked or

distorted.

(4)

Inspect muffler (83) for cracks, breaks, or

excessive burning.

f.

Rescue Saw Filter Assembly, Cylinder Casing, Spill

Filter and Intake Pipe Inspection.

(1)

Inspect cylinder casing (47), filter cap (42),

and filter holder (43) for cracks, dents, or

other damage.

(2)

Inspect prefilter (40) for deterioration and

clogging.

(3)

Inspect main filter (41) for cleanliness and

overall condition.

(4)

Inspect spill filter (69) for cleanliness and

general condition.

(5)

Inspect seal (70) for general condition and

intake pipe (72) for dents, cracks, or other

damage.

g.

Rescue Saw Cutter Blade Assembly Inspection

(1)

Inspect shaft (4), pulley (26), bearings (28)

and 29), spacer (31), flange washers (2 and

3), flange support (6), and support (7) for

distortion, wear, and breaks.

(2)

Inspect cutting arm (14), guard (19), knob (13)

and glade guard (12) for cracks, bends, burns,

and worn threads.

h.

Rescue Saw V-Belt Tensioner Inspection.

(1)

Inspect belt (24) for fraying, stretching and

general good condition.

(2)

Inspect eccentric (23) and spacer (34) for

wear and distortion.

(3)

Inspect push rod (37) and flanges (38) for

wear, cracks, or distortion.

(4)

Inspect spring (22) for wear, distortion or

breaks.

i.

Rescue Saw Handle and Controls Inspection

(1)

Inspect tabular front handle (111) for cracks,

dents, or gouges, and inspect shock absorbers

(114 and 121) for deterioration and general

condition.

(2)

Inspect rear handle (123 and 122) for cracks,

breaks or distortion, and inspect all controls

for general condition.

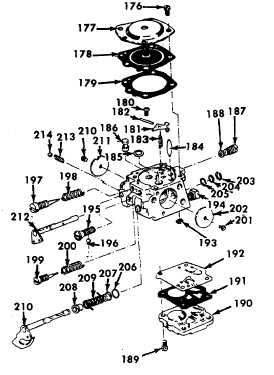

j.

Rescue Saw Carburetor Inspection.

(1)

Check needle points on adjust screws (199)

and 197) and idle screw (195) for wear.

Inspect needle point for ridges, indentations,

or flat spots.

(2)

Check all springs for distortion, crack or

breaks.

5-16

|