|

| |

TM5-4210-229-14&P

4-201.

FRONT AXLE SHAFT AND JOINT ASSEMBLY REPLACEMENT (Continued).

f.

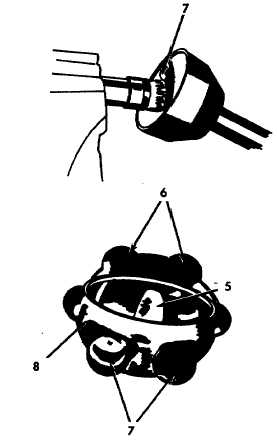

Tilt inner race (5) in outer race (6) until one ball

(7) can be removed, continue this procedure

until all balls (7) are removed. A soft faced

hammer may be used to aid inner race (5)

movement.

g.

Roll universal joint cage (8) at a right angle to

universal joint outer race bell (6) with the two

elongated openings in cage (8) aligned with

opposite teeth of outer race bell (6). Lift cage

(8) and inner race (5) from outer race bell (6).

h.

Inspect axle shaft and universal joint assembly

for seizure, broken or chipped balls, broken

splines or other damage.

i.

Inspect spindle bushing for out of round

condition caused by wear or corrosion, scoring

or roughness in spots.

j.

Inspect axle shaft oil seal for evidence of wear

or damage.

k.

Inspect for evidence of wear due to improper

drive flange shim size. Wear on the interior

surface of ball end of axle housing and on edge

of ball joint bell housing indicates the use of too

thin a shim, allowing contact between the two.

If shim is too thick, the spindle bushing will

show excessive wear.

INSTALLATION

a.

Assemble inner race and cage by indexing

notched tooth of inner race with elongated

opening in cage and rolling inner race into cage.

b.

Align elongated openings of cage with opposite

teeth of outer race bell and lower inner race and

cage assembly into outer race bell.

c.

Tilt-inner race in outer race until one ball can be

inserted, continue this procedure until all balls

are inserted. Pre-lubrication of components and

a soft faced hammer may be used to aid inner

race movement.

d.

Install new lock ring (6) on axle shaft end and

place axle shaft (3) in a vise equipped with soft

jaws.

e.

Place universal joint (1) on top of axle shaft

index end (4) of axle shaft in splined inner

race. Tap end of universal joint shaft with a

soft faced hammer to collapse lock ring,

securing assembly.

f.

Pack

universal

joint

bell

with

lubricant

(Appendix D, Item 21).

When installing axle shaft and universal joint

assembly, care should be taken not to damage axle

shaft oil seal.

Install axle shaft (3) and universal joint assembly (1) in

axle housing indexing splined end of axle shaft with

side gear of center unit (2).

g.

Install steering knuckle and arm.

4-219

|