|

| |

TM5-4210-229-14&P

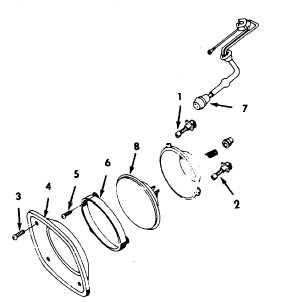

4-94. HEADLIGHTS MAINTENANCE (Continued )

ADJUSTMENT

NOTE

Place the vehicle 25 feet (7.6 meters) from a vertical wall

or structure with the front of the vehicle at a 90 degree an-

gle to the wall or structure.

a.

Measure the height from the ground to the

center of the headlight.

b.

Measure the distance from the center of one

headlight to the other.

c.

Transfer these measurements to the wall or

structure and mark them accordingly with two

cross-marks, directly in front of the headlights.

d.

Turn on the headlights and switch to high

beam.

e.

The focal hot spot of each headlight should be

centered 2 inches (51 mm) below the junction

of the vertical and horizontal marks.

f.

To raise the light, turn the vertical adjusting

screw (1) clockwise. To lower the light, turn

the vertical adjusting screw (1) counterclock-

wise.

g.

To turn the headlight to the left or vertical, turn

the horizontal adjusting screw (2) clockwise.

To turn the headlight to the right of vertical,

turn the horizontal adjusting screw (2) counter-

clock-wise.

REMOVAL

a.

Remove four retaining screws (3) and remove

headlight bezel (4).

b.

Remove three retaining screws (5) and remove

sealed beam unit retaining ring (6).

c.

Pull sealed beam unit from headlight assem-

bly. Disconnect three-way wiring connector

(7)from rear of sealed beam unit (8) and re-

move sealed beam unit (8).

REPAIR

Repair consists of replacing defective sealed

beam unit (8) or bezel (4).

INSTALLATION

a.

Connect three-way wiring connector (7) to new

sealed beam unit (8).

b.

Position sealed beam unit (8) in mounting ring.

Install retaining ring (6) and secure with screws

(5).

CAUTION

Do not overtighten bezel retaining screws.

Overtightening

could

cause

damage

(stripping) of threads in hood fender).

c.

Install headlight bezel (4) and secure with

screws (3).

d.

Connect battery cables.

e.

Check light operation.

4-107

|