|

|||

|

|

|||

|

Page Title:

Synchronizer and Springs Repair. |

|

||

| ||||||||||

|

|

TM 5-4210-224-14&P

6-19. TRANSMISSION REPAIR. (Continued)

e. Synchronizer and Springs Repair.

NOTE

The synchronizer hubs and sliding

sleeves are a selected assembly

and should be kept together as

originally assembled, however the

keys and two springs may be

replaced if worn or broken.

(1) If the relation of hub and sleeve are not marked,

mark them for assembly purposes.

(2) Push the hub from the sliding sleeve. The keys

will fall free, and the springs will be easily

removed.

(3) Place the two springs in position (one on each

side of the hub) so all three keys are engaged

by both springs.

(4)

Place the keys in position and while holding

them in place slide the sleeve onto the hub.

Align the marks made before disassembly.

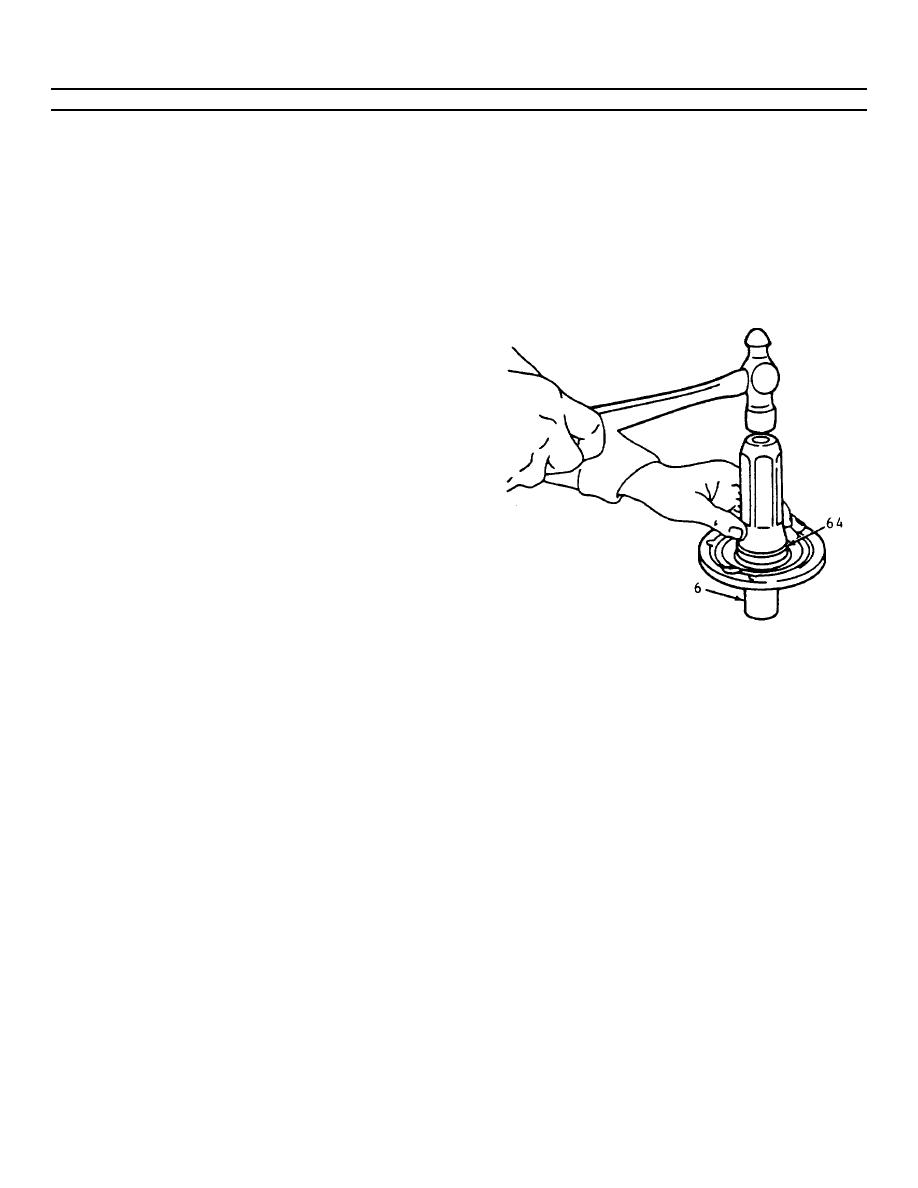

f. Drive Gear Retainer Oil Seal Repair.

(4) Support front surface of retainer (6) in press.

(1) Remove retainer (6) and oil seal assembly (64).

(a) Start seal (64) and tool in retainer bore.

(2) Pry oil seal (64) out of retainer (6).

(b)

Drive seal (64) into retainer (6) until tool

(3) Install new seal (64) on front bearing retainer

flange bottoms on retainer as shown.

seal installer with lip of seal toward tool flange.

(5) Install new gasket (7) on retainer (6) and install

retainer on transmission case (23) when

assembling transmission.

6-38

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |