|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-224-14&P

6-17. CRANKSHAFT AND MAIN BEARING MAINTENANCE. (Continued)

h. Install the number 5 (rearmain bearing cap by

)

c. Apply engine oil (Appendix D, Item 22) to inserts

first applying a thin film of anaerobic sealant

of the proper size and position the plain end

(without the bearing tang) of the insert between

keeping the sealant off the bearing and seal,

the crankshaft and the notched side of the block.

being careful not to get any sealant in the

bearing cap oil relief slot.

d. By rotating the crankshaft, install the insert into

the engine block.

i. Apply a light coat of engine oil (Appendix D, Item

22) to the crankshaft surface that will contact the

e. Remove the tool.

seal, and to the main bearing cap bolt threads.

f.

Apply engine oil (Appendix D, Item 22) to the

CAUTION

lower main bearing inserts and install them to the

The main bearing caps are to be

main bearing caps.

tapped into place with a brass or

leather mallet before the attaching

bolts are installed. Do not use the

NOTE

attaching bolts to pull the main

Measure

the

main

bearing

bearing caps into their seats, as

clearance If the bearing clearance

this may damage the bearing cap

is within specifications: #1,2,3, and

and/or block.

4 = 0.0018 0.0033 inch (.04572

.08383 mm), #5 = 0.0022 0.0037

j. Tap the main bearing cap into place with a brass

inch (.05588 .09398 mm), the

or leather mallet.

bearing insert is satisfactory. If the

clearance

is

not

within

k.

Install the inner bolts and torque to 110 ft-lbs

specifications, replace the insert.

(150 N ).

m

Always replace both upper and

lower inserts as a unit.

l. Install the outer bolts and torque to 100 ft-lbs (135

N ).

m

g.

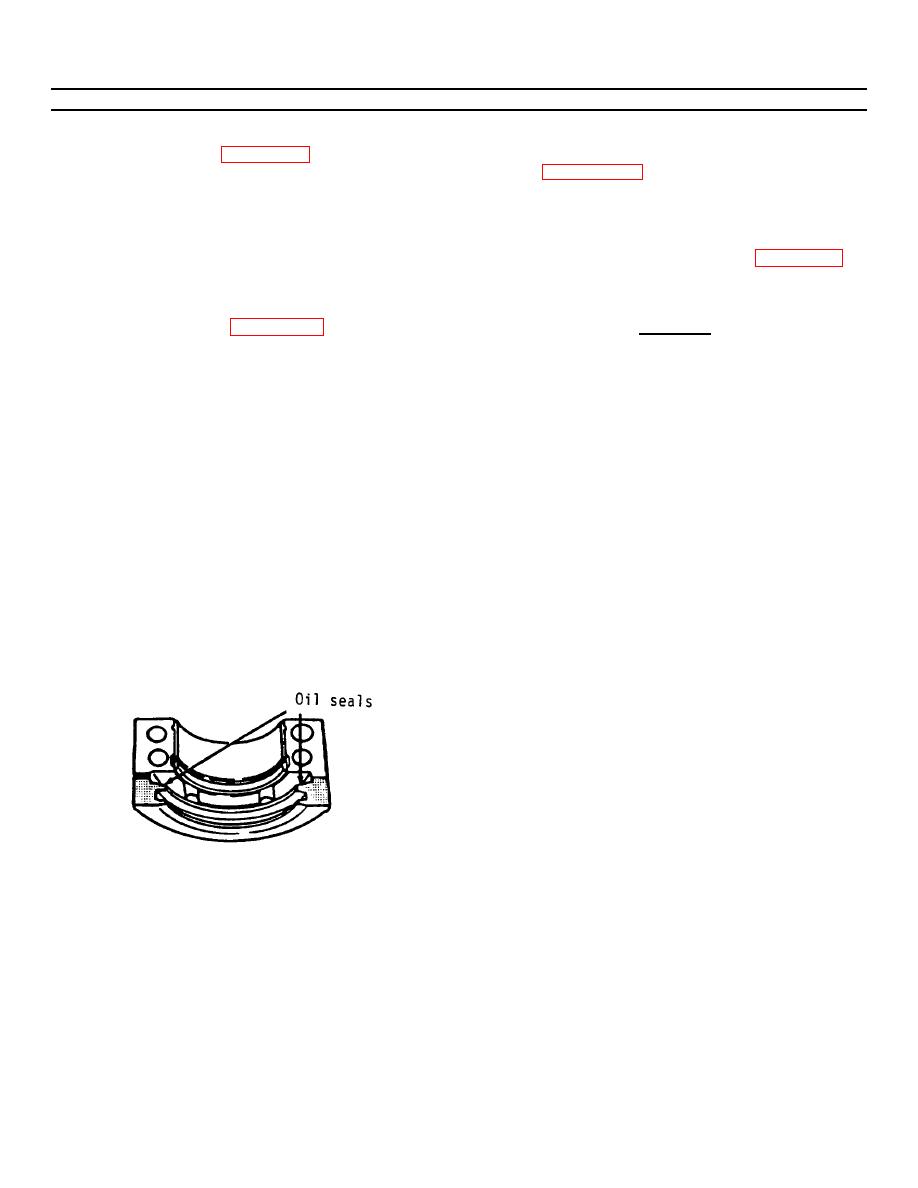

Install rear crankshaft oil seal halves to the

block.

m. Install numbers 1. 2. and 4 main bearing caps

and bolts tightening to same specification and

sequence as number 5. Main bearing caps

steps k and 1.

6-28

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |