|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-4210-224-14&P

6-16.

CONNECTING ROD AND PISTON MAINTENANCE. (Continued)

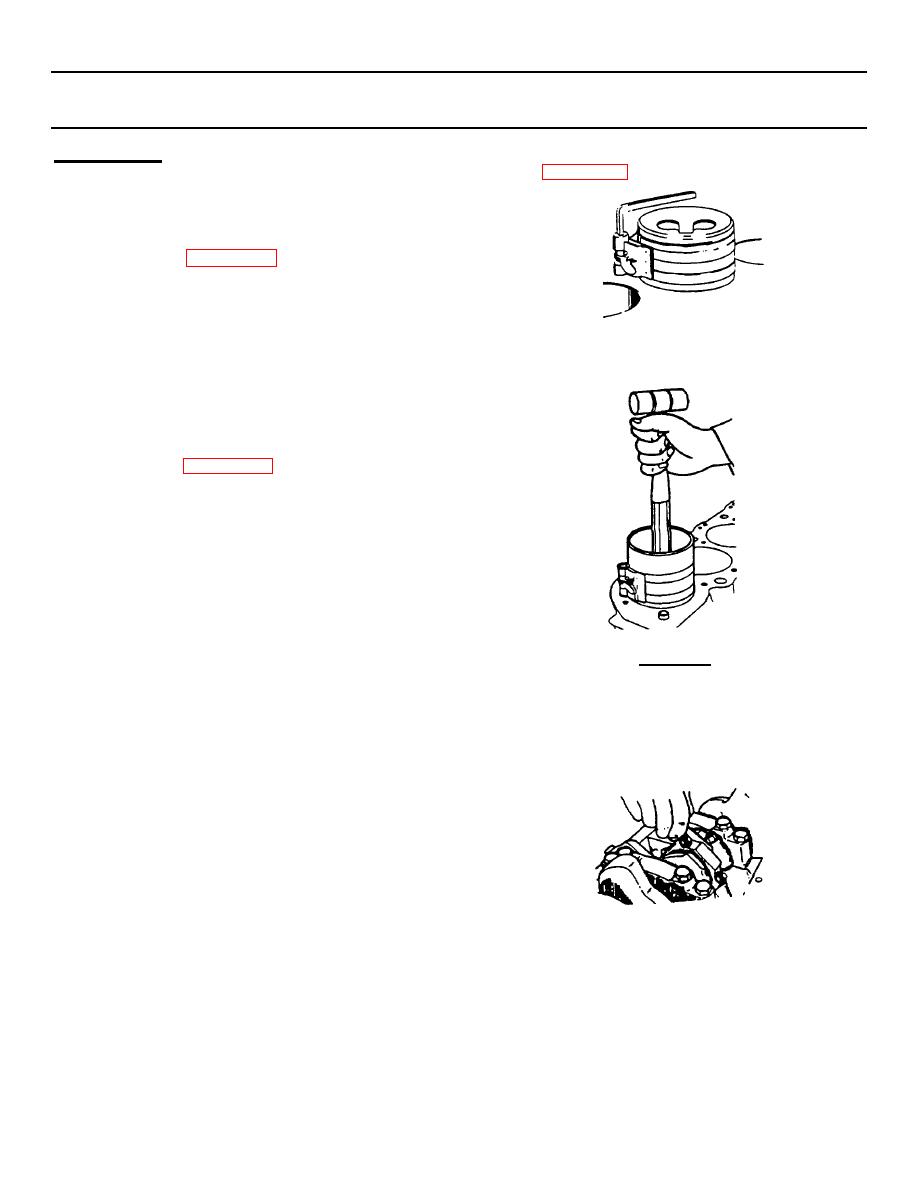

b. Lubricate the piston and rings with engine oil

INSTALLATION

NOTE

Make sure the cylinder walls are clean.

Lubricate the cylinder wall lightly with

engine oil (Appendix D, Item 22).

Install used pistons in the cylinder from

which they were removed. Install new

pistons in the cylinders for which they

c. Locate the piston ring end caps and without

were fitted.

disturbing the ring end cap location, install the

compressor over the piston.

If replaced, be certain that the new

connecting rod bearings are the proper

size.

a. Lubricate the connecting rod bearing with

engine oil (Appendix D, Item 22) and install the

bearings in the connecting rod and connecting

rod cap.

NOTE

Measure

connecting

rod

bearing

clearance. If the clearance exceeds

0.0018 0.0039 inch, select a new,

correct size bearing and remeasure the

clearance.

CAUTION

Each connecting rod and bearing cap

should be marked, beginning at the

The piston must be installed so that the

front of the engine. Cylinders 1,3,5, and

depression in the piston crown is

7 are the left bank and 2,4,6, and 8 are

towards the outside of the engine. The

the right bank. The numbers on the

connecting rod bearing tang slots must

connecting rod and bearing cap must

be opposite the camshaft.

be on the same side when installed in

the cylinder bore. If a connecting rod is

ever transposed from block or cylinder

to another new connecting rod bearings

should be fitted and the connecting rod

should be numbered to correspond with

the new cylinder number.

f. Place the piston in its matching bore and using

light blows with a hammer handle, tap the piston

down into its bore.

6-25

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |