|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-224-14&P

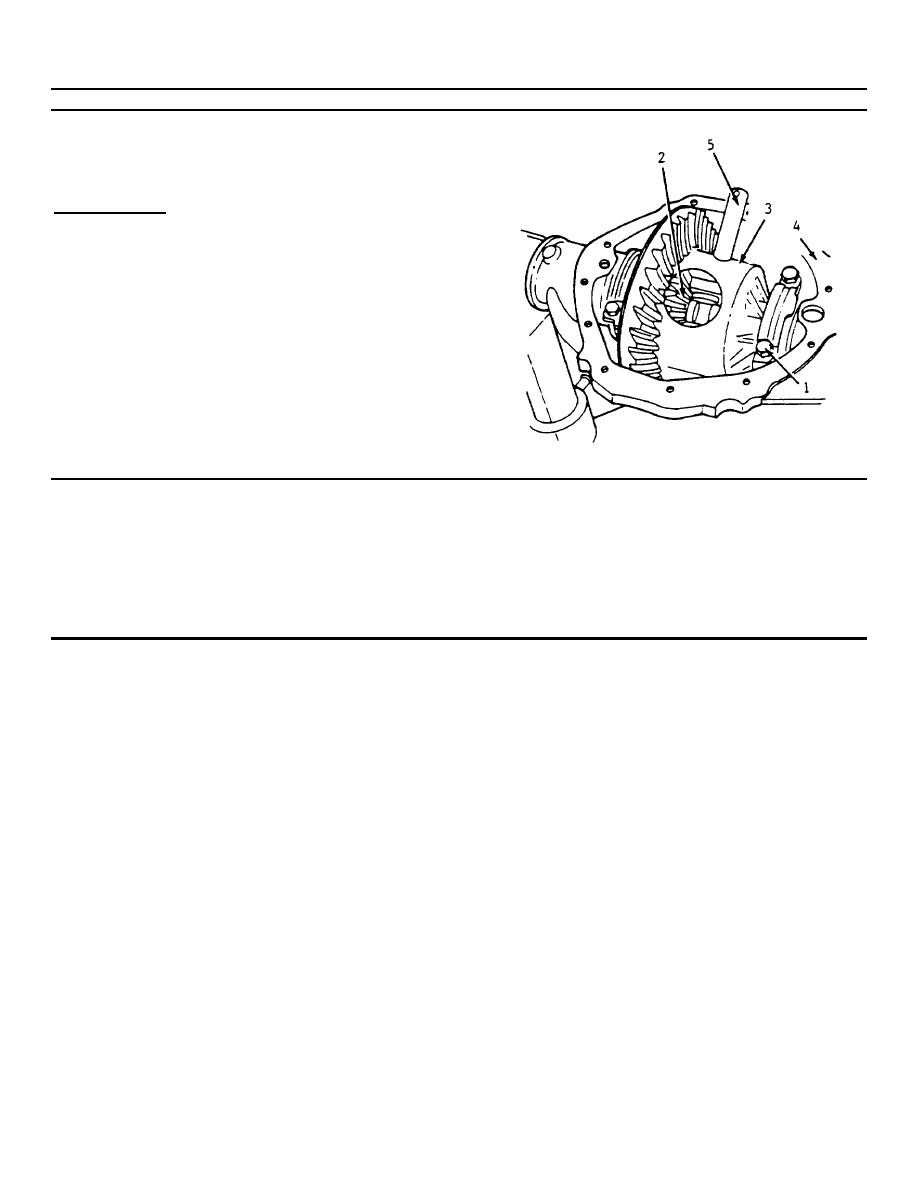

4-246. DIFFERENTIAL SIDE GEAR AND PINION REPLACEMENT (Continued).

d. Record the thickness of the shims removed

from between the bearing retainer flange and

the carrier housing.

INSTALLATION

a. Examine drive pinion head for a pinion depth

code number.

b. Compare depth code number with number on

original pinion. Use the chart below to select

proper shim for preliminary setting of pinion

depth.

CODE NUMBER ON ORIGINAL PINION

+2

+1

0

-1

-2

CODE

+2

-

+.001

+.002

+.003

+.004

NUMBER

+1

-.001

-

+.001

+.002

+.003

ON

0

-.002

-.001

-

+.001

+.002

SERVICE

-1

-.003

-.002

-.001

-

+.001

PINION

-2

-.004

-.003

-.002

-.001

-

The correct shim would be .012 inch

c. Refer to the thickness of the shim recorded

minus .004 inch or .008 inch.

when the pinion was removed. Increase or

decrease the shim thickness according to the

chart. Two examples follow in (1) and (2).

d. Place pinion shim determined in step c above,

into the carrier housing. Ensure bolt holes align

with those of the carrier and that mating

(1) If the original shim measured .014 inch,

surfaces are free of foreign matter.

original code was -1 and new code is +2.

The correct shim would be .014 inch plus

.003 inch or .017 inch.

e. Place pinion retainer assembly into position and

align bolt holes to carrier. Install retaining bolts

and secure in a crosswise pattern. Torque bolts

(2) If the original shim measured .012 inch,

to 65 ft.-lbs.

original code was +2, and new code is -2.

4-347

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |