|

|||

|

|

|||

|

Page Title:

DRIVE BELTS REPLACEMENT - continued |

|

||

| ||||||||||

|

|

TM 5-4210-224-14&P

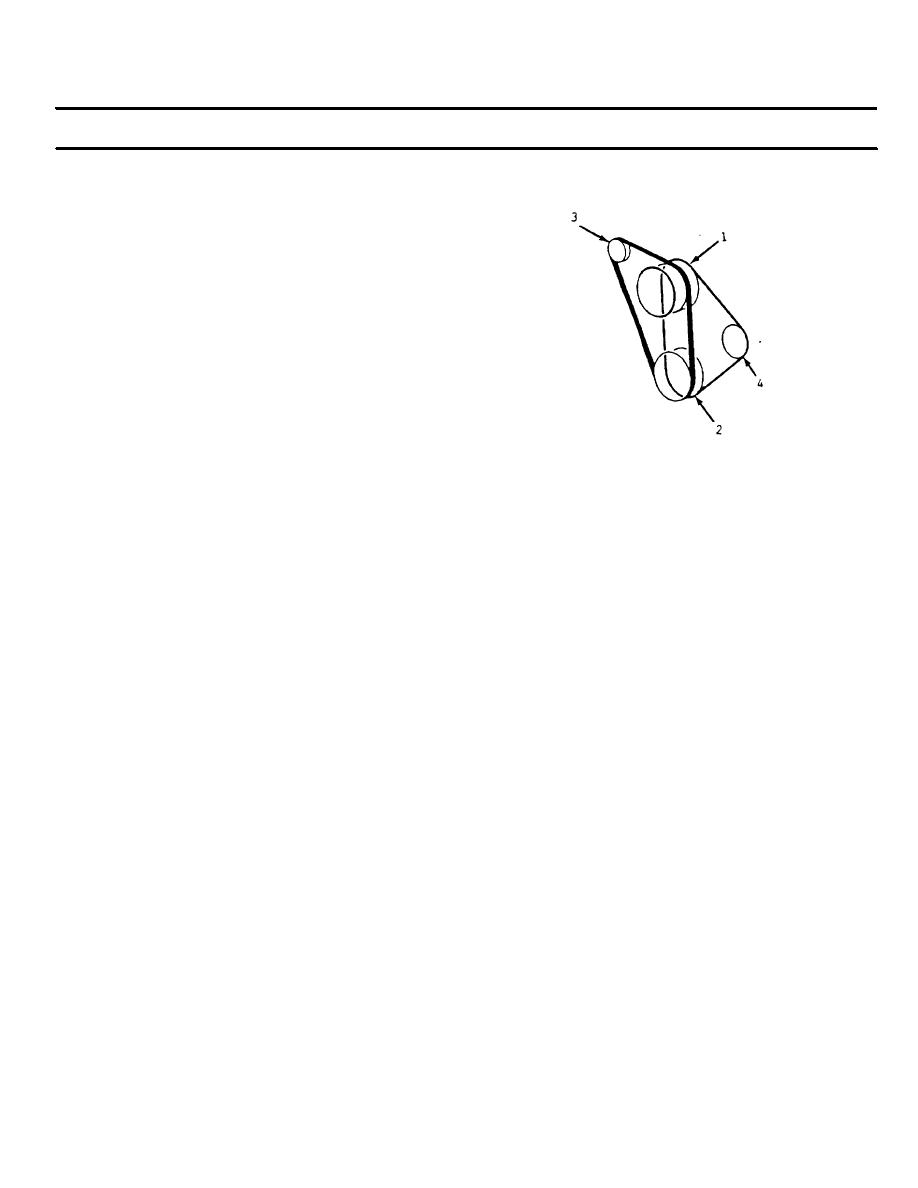

4-76. DRIVE BELTS REPLACEMENT. (Continued).

CAUTION

Avoid over or under-tightening Avoid over

or under-tightening drive belts. Loose belts

result in slippage which can lead to belt and

pulley "glazing", and inefficient component

operation.

Once a belt has become

"glazed", it will be necessary to replace the

belt. Loose belts can also place high impact

loads on driven component bearings due to

the whipping action of the loose belt. Over

tightening belts can lead to bearing damage

and early belt failure.

b. Adjust belt to proper tension specification: New

Belt 146 lb (650 N), Used Belt 67 lb (300 N).

NOTE

A used belt is one that has been rotated at

least one complete revolution on the engine

e. Allow the drive belt to cool.

pulley. This begins the seating of the belt

and it must never be tensioned to new belt

f. Check the belt tension which should be 67 lb

specification.

(300 N).

ADJUSTMENT

c. Tighten the component to the mounting bracket

fasteners as follows:

CAUTION

Generator Adjustment Bolt

Avoid over or under-tightening drive belts.

20 ft-lbs (27 N-m)

Loose belts result in slippage which can

Generator Pivot Bolt

lead to belt and pulley "glazing", and

32 ft-lbs (43 N.m)

inefficient component operation. Once a

Power Steering Adjustment Bolt

belt has become "glazed", it will be

32 ft-lbs (43 N-m)

necessary to replace the belt. Loose belts

Power Steering Pivot Bolt

can also place high impact loads on driven

32 ft-lbs (43 N-m)

component bearings due to the whipping

action of the loose belt. Over tightening

d. Run the engine at idle speed for a minimum of

belts can lead to bearing damage and early

15 minutes, allowing the belt(s) to seat itself in

belt failure.

the pulley(s).

4-115

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |