|

| |

TM 5-4210-220-34

2-13.

FIRE PUMP - Continued

2-13.2

Wearing Ring.

This task covers

Repair

TOOLS

Batteries Disconnected

Shop Equipment, Automotive

(see TM 5-4210-220-12)

Maintenance and Repair,

Heat Shields Removed

NSN 4910-00-754-0705

(see TM 5-4210-220-12)

Pump Suction Pipe Removed

EQUIPMENT CONDITION

(see TM 5-4210-220-12)

Water Tank Drained (see TM 5-4210-220-12)

Main Engine Shutdown

MATERIALS/PARTS

(see TM 5-4210-220-12)

21, Appendix B Petroleum Jelly

APU Shutdown (see TM 5-4210-220-12)

UFP 5351/1 Suction Tube Gasket

REPAIR

(1)

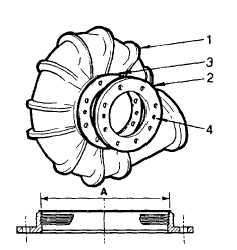

Remove wearing ring (2) using two M10 x 1.5 flat-ended capscrews. Thread the two flat-ended capscrews

into the two tapped holes (4).

(2)

Tighten two capscrews evenly and remove wearing ring (2) from volute body (1).

(3)

Remove and discard gasket (3).

(4)

Examine volute body (1) and wearing ring (2) for cracks, corrosion, or warped flanges. Replace as

necessary.

(5)

Measure the internal diameter (A) of the

wearing ring (2) in several places. If

dimension (A) exceeds 7.025 in. (178.43

mm) at any of several points, the wearing

ring must be replaced. If the wearing ring is

to be replaced, it is recommended that the

impeller

wearing

diameter

is

also

measured. See para. 2-13.4 for procedure.

(6)

To

install

wearing

ring

(2),

apply

a

continuous bead of petroleum jelly (item 21,

Appendix B) to both sides of new gasket

(3).

(7)

Aline mounting holes in gasket (3) with

holes in wearing ring (2). Allow gasket to

stick to wearing ring.

(8)

Attach wearing ring (2) to volute body (1) using eight capscrews (M12 x 1.75 x 25 mm L). Tighten capscrews

to 90 ft lb (122 Nm). Make sure wearing ring is fitted with its sleeve towards the volute body (1).

(9)

Measure radial clearance between the impeller and wearing ring. The minimum clearance allowed is .006 in.

(0.15 mm).

(10) Remove capscrews and replace suction pipe (see TM 5-4210-220-12).

(11) After repairs have been made, test fire pump as detailed in para. 2-13.14.

2-95

|