|

| |

TM 5-4210-220-34

2-12.

PUMP DRIVE AND PTO - Continued

2-12.1

Power Take Off Unit - Continued

(20) Reattach mechanical puller kit to the oil supply end of the PTO housing (1). Tighten pressure screw into

oil supply end of drive shaft (30). Continue to tighten pressure screw until drive shaft is free of spider

gear assembly (24).

(21) Remove drive shaft (30) from PTO housing (1). Bearings (20 and 22) are still mounted on the drive

shaft.

(22) Carefully maneuver spider gear assembly (24) from PTO housing (1).

(23) Disassemble the spider gear assembly (24) following the procedures listed below.

(24) Remove lock ring (41). Pull clutch stop spacer (47), opposing clutch discs (39), and bronze clutch discs

(40) from the spider gear assembly (24).

(25) Compress spring (36) using arbor press. Remove lock ring (38), spring retainer (37), and spring (36).

WARNING

Death or serious injury could occur if compressed air is directed against the skin. Do not use compressed air

for cleaning or drying unless the pressure is/has been reduced to 30 psi (2.11 kg/cm2) or less. When

working with compressed air always use chip guards, eye protection and other personal protective

equipment.

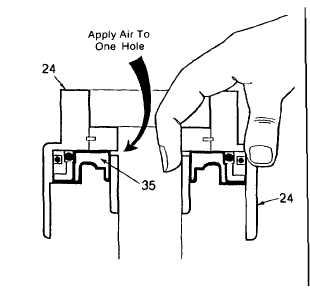

(26) Position spider gear assembly (24) on a

cloth on workbench as shown. Remove

piston (35) by applying compressed air to

one of the clutch oil passages in the spider

gear assembly. Plug the remaining hole

with index finger.

(27) Remove inner and outer block vee rings (33

and 34) from the piston (35).

(28) Inspect bearings (20 and 22) as detailed in

para. 2-7.

(29) If necessary, press damaged bearings (20

and 22) from drive shaft (30) if any damage

is evident. To remove bearing (20) it will be

necessary to remove lock ring (23) from

drive shaft.

b.

Inspection (1) Discard all O-rings, seals, and gaskets

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard’s solvent) is potentially dangerous. Avoid repeated and

prolonged breathing of vapors and skin contact with the liquid. Do not use near open flame, arcing equipment or

other ignition sources. Always wear eye protection and protective clothing. The flash point of P-D-680 is 100 to

138 deg. F (30 to 59 deg. C).

2-70

|